3D PROGRAMS

- The most advanced 3D software (CAD/CAM),

- Quick and easy creation of a 3D model in CAD software

- Efficient programming with a state-of-the-art CAM programme for 5-axis machining

- From simple components to complex assemblies

CAD/CAM SOFTWARE

The latest 3D software. At 3WAY we offer the most efficient CAD/CAM software.

- Fast 3D modelling process

- Creating a mathematical representation of a three-dimensional object

- From simple components to complex assemblies

- The most advanced CAD/CAM software

- Fast 3D modelling process

OUR "BEST" CAD/CAM PROGRAMS...

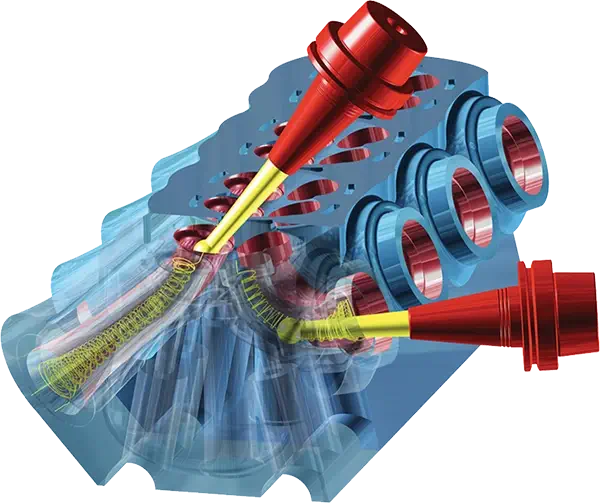

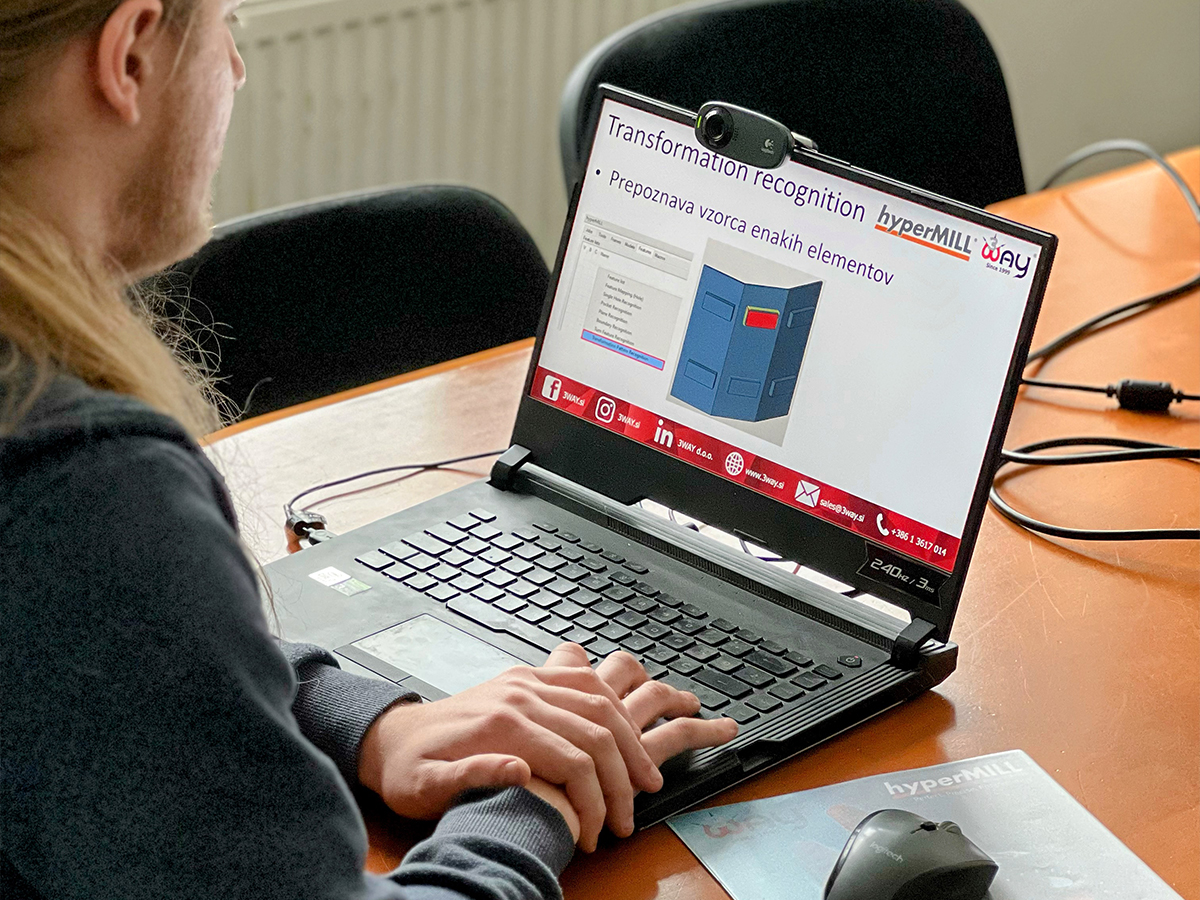

CAM software is a modular and flexible solution for 2.5D, 3D and 5-axis milling and turning. It features high-speed (HSC) and high-performance processing (HPC), all integrated in a single interface.

ThinkDesign is an advanced CAD software package for solid, surface and hybrid modelling. It combines design, engineering and management of the whole product. Easy to use and learn.

Geomagic Design X is the most comprehensive 3D reverse engineering software. It combines CAD modelling with the processing of 3D scan data. In this way, you can create a CAD model that can be modified as you wish

Geomagic Control X is used to control the quality of real parts compared to a CAD model. Advanced tools are available to you. Fast and accurate reporting increases productivity and quality in any production process.

OTHER 3D PROGRAMS...

ThinkLine has more than 10 years of experience in the development of CAD/CAM solutions. The technology enables the development of integrated tools and software solutions to accelerate, streamline and increase the performance of the electrode design and manufacturing process.

Geomagic FreeForm is a unique solution for fast 3D modelling of complex shapes that are very difficult to achieve with other CAD software. It offers us a fast and cost-effective route for designers of original designs or. corrections to scanned data.

PointMaster is one of the leading 3D reverse engineering software. It is designed for applications in mechanical engineering, medicine and science, and is not only easy to use, but also extremely efficient. It is suitable for beginners and experienced professional designers.

PARTSolutions is the ideal solution for companies that use many standard parts from different manufacturers. It is one of the largest 3D libraries, bringing together more than 600 manufacturers. By importing CAD models that have already been made, you can reduce your modelling time.

CAD SOFTWARE

The acronym “CAD” stands for computer-aided drafting. Computers are used to create, modify, analyse or optimise plans. CAD software is used to increase the productivity of the designer, improve the quality of the design, improve the transfer of documentation and create a database for production. CAD software is also helpful in protecting products and inventions.

CAD software is used in a wide range of industries, including automotive, shipbuilding and aerospace, industrial and architectural design (building information modelling), prosthetics and much more. CAD software is also often used to create computer animation for special effects in films, advertising and technical manuals, often referred to as digital content creation.

CAM SOFTWARE

“CAM” stands for computer-aided manufacturing. Using software to control machine tools (CNC) in the production of workpieces. CAM can also refer to the use of a computer to assist in all operations of a production plant, including planning, management, transport, and storage. The primary purpose of CAM software is to create a faster manufacturing process and components and tooling with more accurate dimensions, consistency. The aim is to use the minimum amount of raw materials possible, thus reducing waste and energy consumption.

FAQ - CAD/CAM SOFTWARE

CAD software can be used to create a wide range of models, from simple 2D drawings to complex 3D models. CAD software is used in various industries and sectors because of this.

3-axis machining refers to the movement of the tool along three axes: X, Y, and Z. It is most suitable for relatively simple parts that do not require complex geometry. On the other hand, 5-axis machining allows the tool to move along five axes: X, Y, Z, A, and B. In addition to the three linear axes, 5-axis machines can also tilt and rotate the tool around two additional axes, providing much greater flexibility for complex parts.

The main difference between 3-axis and 5-axis machining is that 5-axis machines can produce more complex parts with greater precision, while 3-axis machines are typically faster and more cost-effective to use.

You can learn more about 5-axis machining with hyperMILL software here.

5-axis machining offers greater efficiency in the manufacturing process.

- Greater precision: The machine easily accesses all sides of the workpiece, resulting in better surface finish and tolerances.

- Greater flexibility: The ability to tilt and rotate the workpiece in multiple directions allows for the creation of more complex shapes and contours.

- Reduced setup time: No need for repositioning.

- Longer tool life: The tool can be tilted to maintain the proper angle throughout the entire machining process, reducing wear.

- Higher productivity: Due to reduced time consumption, productivity increases.

You can read more about 5-axis machining with hyperMILL software here.

“CAM” is a shortened term for CAM software and stands for “Computer-Aided Manufacturing.” CAM refers to the use of computer software for controlling and automating manufacturing processes.

The acronym “CAD” is a shortened term for CAD software and stands for “Computer-Aided Design.” It refers to the use of computers for designing and modeling products.