Complex 5-axis programming and machining with hyperMILL

Haimer and Open Mind Technologies have shown how complex milling operations can be handled in a powerful and dynamic way. Haimer is a big fan and supporter of the Augsburger Panther hockey team in the German Hockey League. A prestigious supplier of CNC machine tool systems took this as an opportunity to showcase the capabilities of their tools and tool holders by creating a panther model. The CAM experts at Open Mind Technologies tackled the challenging task of programming using their hyperMILL software.

“AUSBURGER PANTHER” – THE HOCKEY TEAM

The “Augsburger Panther” is a team of the German Hockey League (DEL) and is the most famous “Panther” in these parts. Haimer GmbH is a proud sponsor of this professional hockey team. They are the market leader in high-precision tools for processing metal parts. They came up with the ingenious idea of making a panther out of aluminum in their center. The Panther is a real masterpiece, proving that 5-axis milling with Haimer holders and tools can be compared to hockey in terms of speed, power, and dynamics.

"Hockey is not just about speed and raw force. Each player must have excellent technical skills and contribute to a perfect team game. Haimer works in a very similar way by incorporating the perfect synergy of its high-tech products for state-of-the-art CNC machines and the best CAD/CAM software.”

MILLING - A TEAM SPORT

When looking for “teammates” to manufacture the panther, the Haimer company turned to Open Mind Technologies, where they develop hyperMILL CAM software. hyperMILL is considered by many engineers to be the leading software in 5-axis machining, making Open Mind Technologies the best option when it comes to completely freeform contour programming. Without hesitation, they confirmed to participate in the programming of this unusual exhibit. Head of Global Engineering Services, Christian Neuner, explains: “A model like this is a great opportunity to test the versatility and flexibility of our software. hyperMILL has many features that allow CAM users to really test the power of the machine to achieve the desired goal.”

They chose a 5-axis CNC machine DMG MORI HSC70, which is ideal for precise surface processing of aluminum.

HAIMER OFFERS TOOLS FOR ALL CHALLENGES

Machining the panther’s head proved particularly challenging, especially in the mouth and incisors. The processing of the long and thin tail was also demanding, as it is extremely sensitive to vibrations. Due to the difficult areas to reach, milling was extremely difficult, so engineers decided to make the statue in two layouts.

What I found most helpful for me while working on this project was the fact that all the HAIMER holders and tools were also available in the form of DXF and STP files. The models are available on the HAIMER home page for easy download. It takes just three clicks of the mouse in our hyperMILL® Toolbuilder to enter them into the database. After this, they are immediately ready for programming and simulation.”

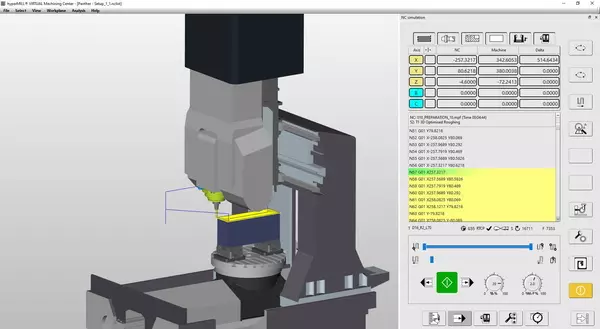

CAD FOR CAM SIMULATION IN hyperMILL

Creating a visually appealing model required superb programming. hyperMILL expert Jakob Nordmann explains: “For especially detailed areas, like the mouth and tail section or with the creases of the joints, we generated additional surfaces that can be combined with the STL network in hyperMILL.” For this purpose, Nordmann used hyperCAD-S, a “CAD for CAM” system specially designed by Open Mind Technologies to meet all the needs of programmers.

Because the limited space required different tool angles, he focused on maintaining accurate line spacing and transitions without visible gaps. Nordmann reveals: “This allowed me to determine the entire toolpath and divide it into sections, which then allowed me to edit at different angles with different tools. It saved me a lot of time.” Equally necessary before actual machining was a virtual machining center. hyperMILL Virtual Machining is a safe solution for NC simulation, where the movements of the virtual machine fully imitate real machine movements and ensure reliable collision detection.

It took the team about three intense weeks to complete the first panther statue. The panther will also stand in the tunnel between the dressing room and the halls so that the players will always have high motivation when they step on the ice.