At 3WAY we answer the most frequently asked questions (FAQ) about 3D printers, 3D scanners and CAD/CAM software and services using 3D technology.

3D PRINTERS AND 3D PRINTING

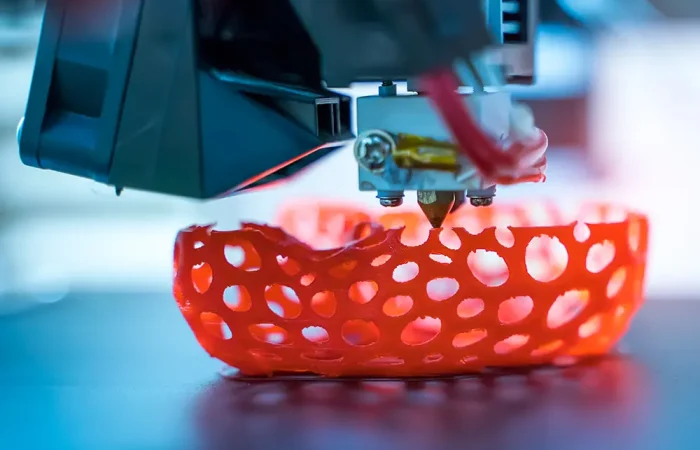

3D printing is the process of creating three-dimensional objects from a digital (CAD) model. It enables efficient and fast creation of extremely complex shapes. It is an additive process in which layers of material are sequentially deposited in various forms. This distinguishes it from traditional manufacturing techniques, which involve the removal of material through methods.

You can read more about 3D printing and 3D printers here.

3D printing offers numerous solutions in various fields. The applications of 3D printing are widely extensive due to few limitations:

- Prototyping: Rapid production of a real piece from a CAD model

- Production of functional 3D parts: Functional components with exceptional mechanical properties

- Medicine: Production of prosthetics, implants, and even organs

- Art and design: Creating unique objects

- Education: Learning about 3D technology

- Aerospace industry: Production of lightweight and complex components

- Automotive industry: Manufacturing spare parts, molds, prototypes

You can read more about the utility of 3D printing and 3D technology in general here.

As you enter the world of 3D printing, sooner or later, you start thinking about which filament you need for 3D printing. Here are some of the most commonly used:

- PLA (Polylactic Acid): Biodegradable material of plant origin. It has minimal requirements and is easy for 3D printing. Compatible with a wide range of 3D printers.

- ABS (Acrylonitrile Butadiene Styrene): Excellent mechanical properties – resistant to higher temperatures and UV light.

- PETG (Polyethylene Terephthalate Glycol): A blend of PLA and ABS filament. An ideal combination of strength and flexibility. Good mechanical properties.

You can read more about 3D printing filaments here.

Buying a 3D printer can make many tasks easier, but you need to ask yourself several questions before you find the right 3D printer for you:

- Needs and goals

- Type of 3D printer

- 3D printing volume

- Compatible materials (what products will you be printing?)

- Prior knowledge

- Budget

Look at which 3D printer is right for you here.

Here are the most common 3D printing technologies:

- Fused Deposition Modeling (FDM): The most popular 3D printing technology, where the 3D printer deposits filament layer by layer through a nozzle.

- Stereolithography (SLA): Uses a laser to solidify liquid resin.

- Selective Laser Sintering (SLS): Uses a laser to sinter powder material.

- Digital Light Processing (DLP): Uses a light projector to solidify liquid resin.

- Material Jetting (MJ): Uses inkjet printing heads to spray liquid photopolymers onto a build platform layer by layer to create an object.

- Direct Energy Deposition (DED): Uses a directed energy source (such as a laser or electron beam) to melt and deposit material.

All 3D printing technologies have their own advantages and limitations. You can learn more in the article.

3D SCANNERS AND 3D SCANNING

In the market, there are various types of desktop and metrology 3D scanners that differ in how they capture 3D data. Some of them are:

- Laser 3D scanners,

- Structured light,

- Photogrammetry,

- Handheld 3D scanners,

- CMM

You can read more about different types of 3D scanners here.

3D scanning offers applications in various fields, such as:

- Reverse engineering: designing and developing new products or modifying existing ones,

- Quality control in manufacturing: monitoring the quality of parts, molds, or tools during the manufacturing process,

- Architecture and construction: assisting in the design and planning of new structures.

- Art and culture: creating digital replicas of artworks and artifacts, enabling their preservation and detailed study without risking damage to the originals,

- Medicine and dentistry: creating patient-specific models, prosthetics, and implants,

- Entertainment and media: creating 3D models of characters and objects for use in movies, video games, and other forms of media.

You can read more about the utility of 3D scanning here.

The time required for 3D scanning of an object is influenced by several factors:

- The size of the object,

- he complexity of the object,

- The type of 3D scanner,

- The requirements for capturing details.

Capturing a small and simple object can take a few minutes, while 3D scanning a larger and more complex object can take several hours. You can read all about 3D scanning of objects here.

Of course, we also offer 3D scanner rental services. We have a wide range of different 3D scanners available for various needs, so you will certainly find the right one. Many people become very enthusiastic about 3D scanning due to all the advantages and later implement this form of 3D technology into their business.

You can read all about different 3D scanners here.

3D scanners have several common features with cameras. Cameras gather information about colors, while 3D scanners gather information about distance. The image projected by a 3D scanner determines the 3D position of each point.

You can read all about 3D scanners here.

The accuracy of our 3D scanners reaches up to 0.005 mm, placing them at the very top of quality. Usually, the accuracy requirements are not that high, which speeds up the entire 3D scanning process.

You can read all about 3D scanners here.

3D scanning is the process of digitally capturing an object. The result of 3D scanning is a CAD model.” It’s one of the fastest-growing 3D technologies that can enhance your competitiveness in the market. You can use the data obtained by a 3D scanner for reverse engineering or quality control..

You can read all about 3D scanning and 3D scanners here.

CAD/CAM SOFTWARE

CAD software can be used to create a wide range of models, from simple 2D drawings to complex 3D models. CAD software is used in various industries and sectors because of this.

You can read more about CAD software here.

3-axis machining refers to the movement of the tool along three axes: X, Y, and Z. It is most suitable for relatively simple parts that do not require complex geometry. On the other hand, 5-axis machining allows the tool to move along five axes: X, Y, Z, A, and B. In addition to the three linear axes, 5-axis machines can also tilt and rotate the tool around two additional axes, providing much greater flexibility for complex parts.

The main difference between 3-axis and 5-axis machining is that 5-axis machines can produce more complex parts with greater precision, while 3-axis machines are typically faster and more cost-effective to use.

You can read more about 5-axis machining with hyperMILL software here.

5-axis machining offers greater efficiency in the manufacturing process.

- Greater precision: The machine easily accesses all sides of the workpiece, resulting in better surface finish and tolerances.

- Greater flexibility: The ability to tilt and rotate the workpiece in multiple directions allows for the creation of more complex shapes and contours.

- Reduced setup time: No need for repositioning.

- Longer tool life: The tool can be tilted to maintain the proper angle throughout the entire machining process, reducing wear.

- Higher productivity: Due to reduced time consumption, productivity increases.

You can read more about 5-axis machining with hyperMILL software here.

“CAM” is a shortened term for CAM software and stands for “Computer-Aided Manufacturing.” CAM refers to the use of computer software for controlling and automating manufacturing processes.

You can read more about CAM software here.

The acronym “CAD” is a shortened term for CAD software and stands for “Computer-Aided Design.” It refers to the use of computers for designing and modeling products.

You can read more about CAD software here.