Shining3D OptimScan Q12 – 3D scanner

OptimScan Q12 is a highly accurate industrial 3D scanner with four 12.3 MP cameras, two scanning ranges, support for automation and MSF technology for capturing complex details. It is ideal for quality control, reverse engineering and use in the automotive and aerospace industries.

All prices incl. VAT.

Main features

- High accuracy and resolution

- Dual scanning range

- MSF (Monocular-Stereo Fusion) technology

- Flexible scanning modes (manual, automatic, semi-automatic)

- Full integration into industrial processes

OptimScan Q12 scanner with exceptional accuracy and speed

The OptimScan Q12 is a professional 3D scanner from Shining3D. It is equipped with four 12.3 MP cameras that enable detailed surface capture without loss of detail. The system ensures speed and reliable results for quality control, reverse engineering or CAD model comparison.

Three scanning modes

Automated quality control

Monocular-Stereo Fusion (MSF)

Dual scanning range

The 3D scanner includes two scanning ranges. Switching between them is easy with just one click. You can adjust the measurement field to the size of the scanned objects. You can choose a large scanning range for objects up to 430 x 300 mm or a smaller scanning range for objects up to 160 x 110 mm. Data scanned from different ranges can then be seamlessly merged in the software, ensuring efficiency while maintaining exceptional accuracy.

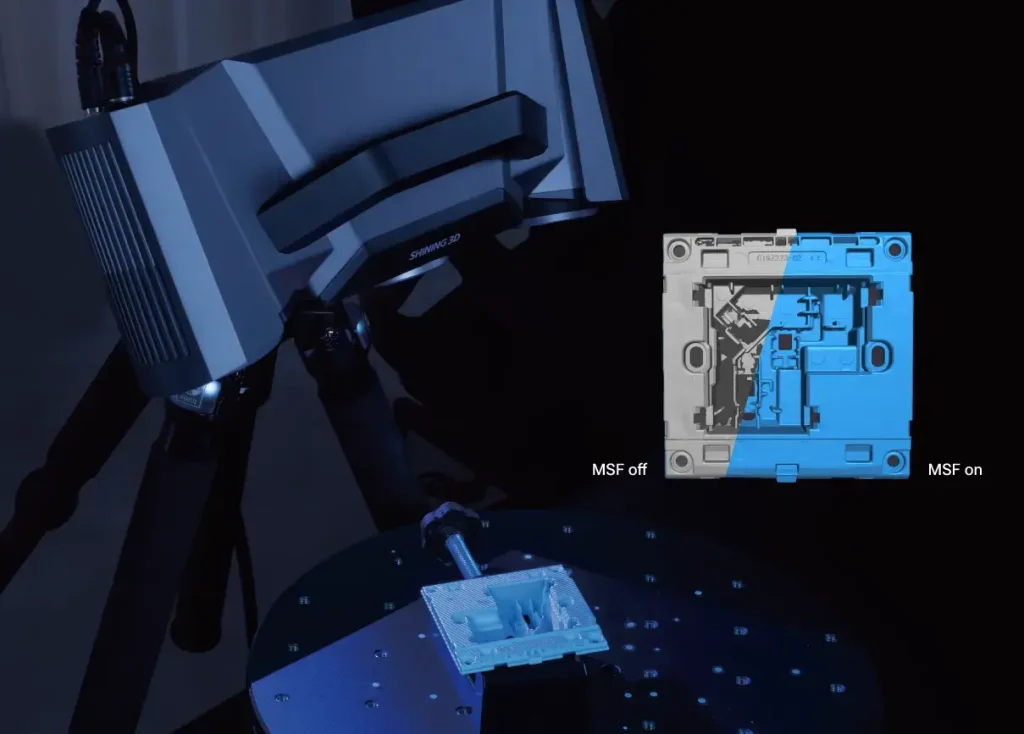

Monocular-Stereo Fusion (MSF) in the OptimScan Q12

MSF is a feature that helps the 3D scanner capture more data with greater accuracy, which is especially important for more complex parts such as edges or joints on industrial components.

Adjustable measurement system of the 3D scanner

The OptimScan Q12 is an extremely compact 3D scanner that is easy to carry and flexible for versatile scanning. It offers manual scanning, semi-automated scanning and fully automated scanning. For semi-automated 3D scanning, a fixed tripod and an automatic rotary table are used. For fully automated scanning, the scanner is connected to a robot to perform repetitive inspection tasks.

Seamless automation integration with OptimScan Q12

The 3D scanner is designed for integration into existing industrial production lines. Its system is compatible with automated robots and other manufacturing systems. This enables fully automated 3D quality control, where measurement results are detected and processed in real time without human intervention.

The workflow for integrating the scanner into an existing industrial line takes place in four steps. The first step is setting the robot’s path. The second step is automated 3D scanning. This is followed by automated data analysis. Finally, automated report generation completes the process.

3D scanner suitable for use in various industries

The OptimScan Q12 performs excellently in the aerospace and automotive industries, as well as other sectors where exceptional accuracy is crucial. It is suitable for 3D measurements and SPC (Statistical Process Control) in production, reverse engineering and rapid CAD model creation, quality control of critical components and tools and precise documentation and data archiving.

Specifications

|

Scanning range (FOV) |

Small: 160 × 110 mm |

Large: 430 × 300 mm |

|

Point distance |

0.005 mm |

0.015 mm |

|

Depth of Field |

60 mm |

300 mm |

|

Accuracy |

0.005 mm |

0.015 mm |

|

Working distance |

210 mm |

590 mm |

|

Light source |

Blue LED |

|

|

Resolution |

4 × 12.3 MP |

|

|

Net weight |

3,5 kg |

|

|

Certifications |

CE, FCC, ROHS, WEEE, KC, FDA, NUKCA, IP50, TELEC, TiSAX |

|

|

Acceptance test |

VDl/VDE 2634 Part2 (certified in ISO 17025 certificated accuracy lab) |

|

| Weight | 3,5 kg |

|---|---|

| Dimensions | 366 × 162 × 132 mm |

| Brand | |

| Model | |

| Barvno 3D skeniranje |

Reviews

There are no reviews in english yet.