“Mini” is even faster with hyperMILL CAM software

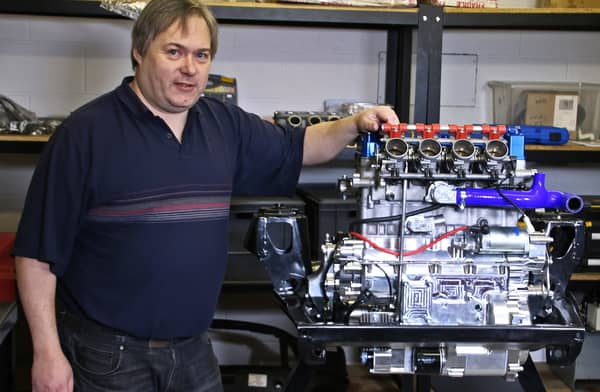

Vetech has used its know-how to modify the Suzuki Hayabusa engine for use in the Mini. All the leading CAM software developers were given a model of the gear selector shaft and asked to program it. V

Open Mind Technologies

have with their

hyper

MILL

CAM software, they have provided the most efficient solution.

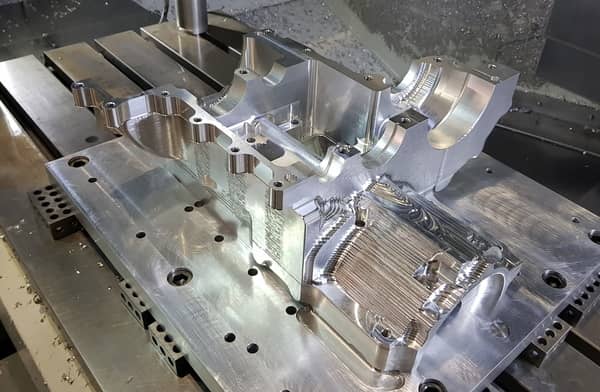

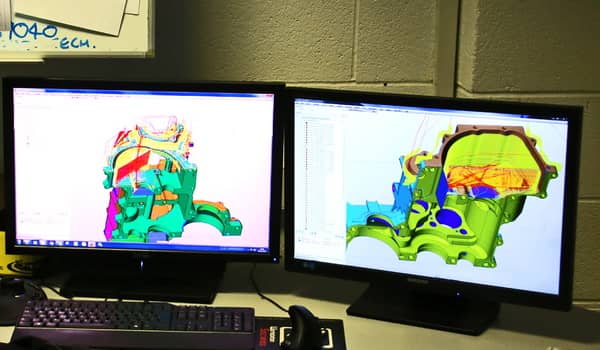

At Vetech Product Design & Development, which designs and manufactures complex tooling for aluminium moulds, military sensors and the innovative Hayabusa engine, the previous CAD/CAM system struggled to cope with the complexity of the components. This is where the expertise of the company’s engineers comes into its own

Open Mind Technologies

, a developer of CAM software.

hyperMILL HAS RESTORED CONFIDENCE ABOUT COLLISIONS DURING PROCESSING

Vetech was using an outdated CAD package with an integrated CAM system for all machining tasks. One day, the VMX42M made a quick move between two points, hitting the wiring and destroying the spindle. This resulted in weeks without a machine while a new expensive spindle had to be installed. Vetech had to replace its CAM software due to poor crash detection. She convinced them

hyper

MILL

CAM software.

hyperMILL CAM SOFTWARE PROVES TO BE THE BEST CHOICE

When the 1300cc Hayabusa engine was rebuilt to fit into the Mini, the gearbox position had to be changed and a reverse gear added. They tried to program the gear selector shaft, but the task was almost impossible with the old software. All the leading CAM developers have been entrusted with the programming of this piece.

Collision avoidance was certainly a critical factor.

hyper

MILL

certainly convinced Vetech’s engineers on this point and provided the most effective solution compared to other programmes. In addition, they had to achieve faster programming times for aluminium mould tools –

hyper

MILL

was once again way ahead of the pack when it came to programming mould tools.

hyperMILL CAM SOFTWARE PROVES TO BE THE BEST CHOICE

Vetech has certainly benefited greatly from hyperMILL in programming the eleven basic components of the redesigned engine. The ability to program and machine complex parts with confidence in the collision avoidance system is of paramount importance to Vetech. V

Open Mind Technologies

have programmed a system with chucks, spindles, tool holders and a 4-axis rotary table, all integrated into one model.

To test the time reduction, they programmed an aluminium forming tool for the inlet and exhaust covers. The previous system took 20 hours to programme, with

hyper

MILL

the same tool was completed in less than 10 hours. The upper casing of the engine consists of seven individual settings. With the previous CAM package, Vetech was unable to transfer the basic model from one process to another.

"hyperMILL has reduced programming time and cycle time on the machine. The introduction of this CAM software has also improved the quality of surface finish, repeatability of our parts and mould tooling."

hyperMILL CAM SOFTWARE PROVES TO BE THE BEST CHOICE

More than 60% of Vetech’s work is in the production of mould tools for aluminium moulds, so it is important for them to reduce delivery times for their customers. In most cases, they are expected to design, programme and build the mould tooling, design the plastic prototypes and carry out all the necessary tests in 3-4 days. To achieve this, programming times must be short and processing extremely efficient.

SHORTER PROGRAMMING AND PROCESSING TIME ON THE MACHINE

It took 8 days to program the tool with the previous software.

hyper

MILL

made the same process possible in three days, which means more than 60% faster programming. On the other hand, cultivation strategies have reduced cycle times by a further 50%.

In addition, the quality of surface treatment, the reproducibility of the end products and the mould-making tools have improved. Open Mind Technologies has achieved thatVetech has regained 100% confidence in its machining strategies and toolpaths, thanks to an outstanding anti-collision system.