3D PRINTING OF FUNCTIONAL PARTS WITH INTAMSYS FUNMAT PRO 610 HT

3D printing

has evolved to become a key tool for designers, engineers and manufacturers. 3D printing, also known as additive manufacturing, allows the creation of complex shapes and structures by adding material layer by layer. In this newsletter, we will focus on 3D printing functional parts in PEEK, PEEK, ULTEM and PPSU materials and their applications in various industries. In addition, we will present the “beast” of FDM 3D printing –

Intamsys Funmat Pro 610 HT

.

FUNCTIONAL PARTS ARE MADE MORE TIME AND COST-EFFECTIVELY WITH THE HELP OF 3D PRINTING

Functional parts have a specific function and are intended to be incorporated into the finished product. They are different from prototypes in that they are intended for final use. There are several polymer 3D printing technologies used to produce functional parts – Fused Deposition Modelling (FDM), Stereolithography (SLA) and Selective Laser Sintering (SLS). This time we will focus on FDM 3D printing technology, highlighting the Intamsys Funmat Pro 610 HT. It is an industrial 3D printer, which is ideal for 3D printing functional parts made of PEEK, PEKK, ULTEM and PPSU materials.

ADVANTAGES OF 3D PRINTED FUNCTIONAL PARTS

3D printing functional parts offers several advantages over traditional manufacturing methods. Firstly, it is cost- and time-efficient to produce, and it is possible to reproduce and redesign quickly. In addition, 3D printing offers a lot of customisation, allowing the creation of unique and specialised parts. Over the years, the quality of 3D printed functional parts has improved. Today, they are reliable, durable and powerful, making them suitable for use in a wide range of industries such as automotive, aerospace and medical. They often have the advantage of being lightweight.

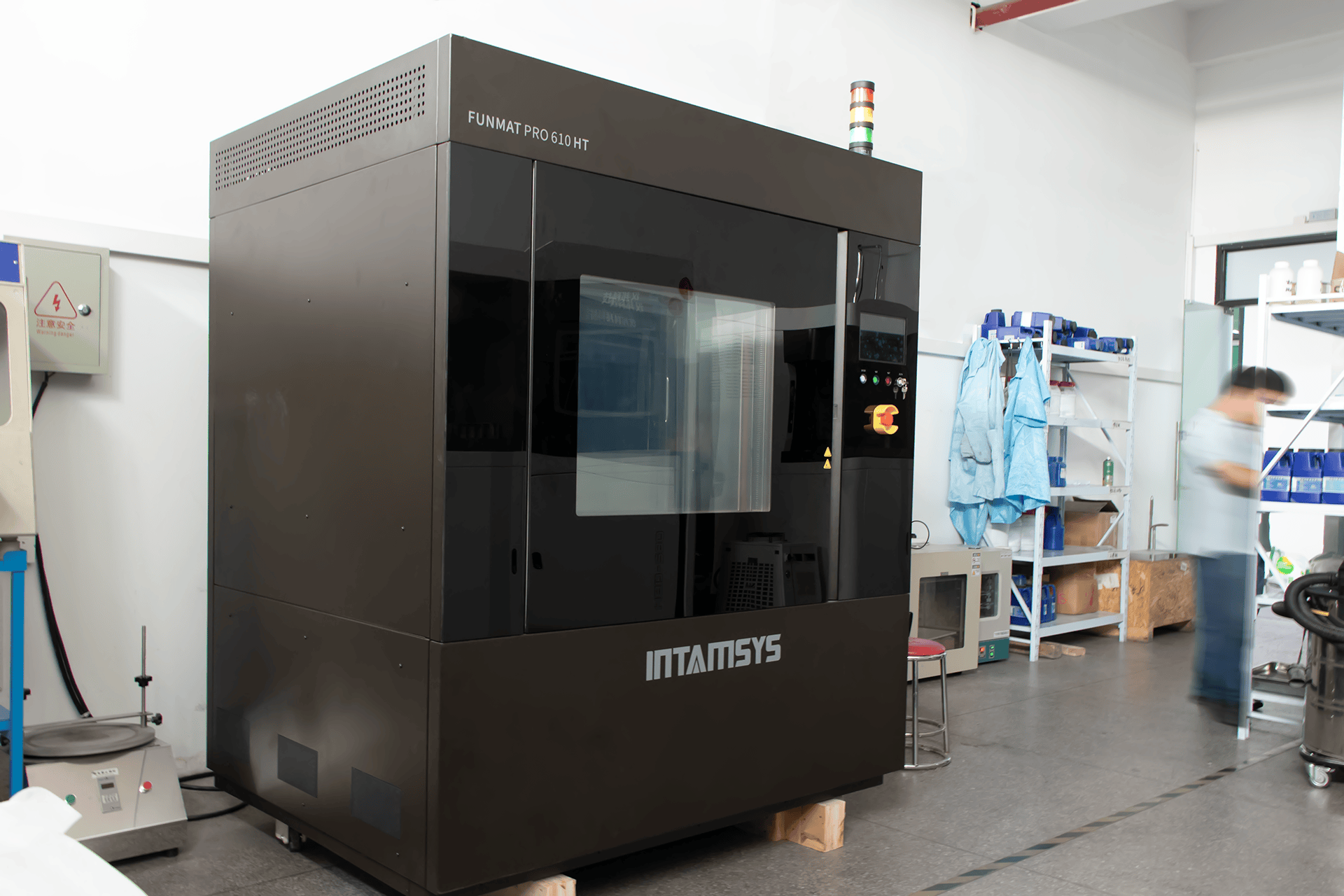

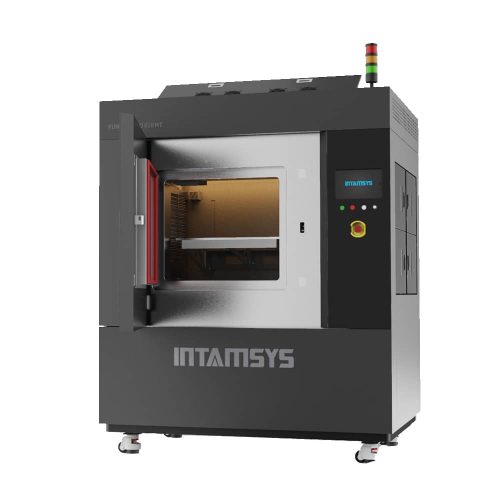

3D PRINTING OF FUNCTIONAL PARTS WITH INTAMSYS FUNMAT PRO 610 HT

Intamsys has confirmed its position as a leader in industrial 3D printing with the launch of the Funmat Pro 610 HT 3D printer in 2019. The high-performance FDM system with advanced features offers 3D printing volumes up to 610 x 508 x 508 mm. The Funmat Pro 610 HT has two extruders, the nozzles can be heated up to 500°C and the closed heated chamber can hold temperatures up to 300°C.

The Funmat Pro 610 HT is specifically designed to produce large functional parts for end-use applications. It is designed to 3D print the highest performance engineering polymers on the market – PEEK, PEKK, ULTEM and PPSU. 3D printing with the Intamsys Funmat Pro 610 HT ensures the highest quality of functional parts.

HOW WAS THE INTAMSYS FUNMAT PRO 610 HT DESIGNED AND BUILT?

In the company

Intamsys

have always placed great emphasis on precise temperature control. Building a machine with a chamber that can withstand 300 °C was also a difficult feat for them, as the internal components had to be tested at extremely high temperatures.

Thanks to Intamsys’ existing portfolio of industrial 3D printers, the team was able to prototype a number of internal components using engineering materials. This has eliminated the need for metal prototypes and reduced costs. Outsourcing the production of functional prototypes would consume significantly more resources. They were therefore built in-house, which also allowed them to do more customisation and testing. Some parts have been tested in dozens of different iterations with minor design changes to optimise each component.

This has also significantly reduced dependency on others and shortened delivery times. Today, a total of 15 different 3D printed functional parts are installed in each Funmat Pro 610 HT unit.

FDM 3D PRINTING TECHNOLOGY OFFERS FAST AND EFFICIENT SOLUTIONS

FDM 3D printing technology can solve the problem of a shortage of functional or spare parts, which are made from high-performance materials and offer high mechanical and thermal resistance. High-performance 3D printed functional polymer parts are corrosion resistant and have high strength. This is especially true for high performance materials such as PEEK, PEKK, ULTEM, PPSU, and engineering materials such as PC, PA, ABS.