3WAY Open House 2022″ is under roof!

We would like to thank all visitors for attending the “3WAY Open House 2022”! We are delighted to have brought the event to a successful conclusion. We believe that the participants have been given a sufficiently illustrative presentation of potential solutions for their business and have taken away some new knowledge or broadened their horizons through the lectures. We certainly look forward to doing it again in 2023!

On Friday, 11.11.2022, our second “3WAY Open House” took place. After a successful 2019 edition, this time we have gone one step further and offered participants even more quality content in our lectures.

HOW DID THE 3WAY OPEN HOUSE GO?

Our participants were welcomed with fragrant coffee and delicious croissants. Once most of us were assembled, a short presentation of 3WAY by our CEO was scheduled as an introduction. At 3WAY we are involved in everything related to cutting-edge 3D technology, i.e. 3D printers, 3D scanners and CAD/CAM software.

Almost all of the 3D printers and 3D scanners that we have on display as DEMO units were on display at the side of the hall where they were exhibited for our participants to see during the breaks and afterwards. This year we wanted to do a real Open House – we brought practically everything that is in our house, and if you went to our premises at that time, all you would find is office chairs and desks.

In addition to sales, demand for services is also on the rise, setting 3WAY apart from the competition. Anyone can do sales, although there are differences within that too. At 3WAY, we stand behind our products and offer training and support to our customers after purchase. Our experts’ knowledge and experience is particularly evident in the area of services, where they find an efficient solution to every demand. We strive to be as fast, accurate and consistent as possible in our service, but above all, the job must leave our hands perfectly done. In short, 3WAY certainly differentiates itself from the competition by its knowledge and integrated services.

3WAY TEAM

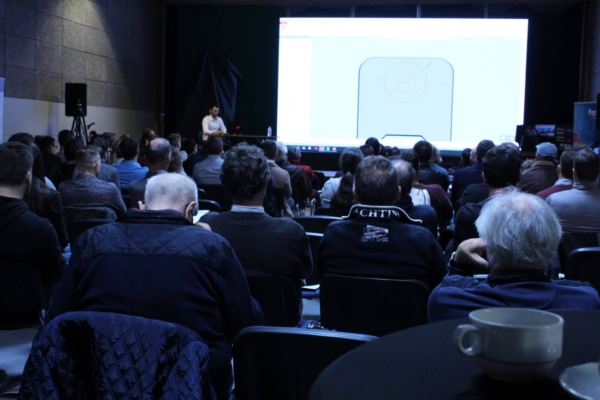

hyperMILL CAM SOFTWARE

In terms of technical lectures, visitors could initially improve or build up their knowledge in the “hyperMILL & Additive Manufacturing” lecture, which was led by our own Lovro. At 3WAY, we have been behind Open Mind Technologies ‘ hyperMILL CAM software from the very beginning, as we believe it is the best in the CAM field, especially at the forefront of 5-axis machining.

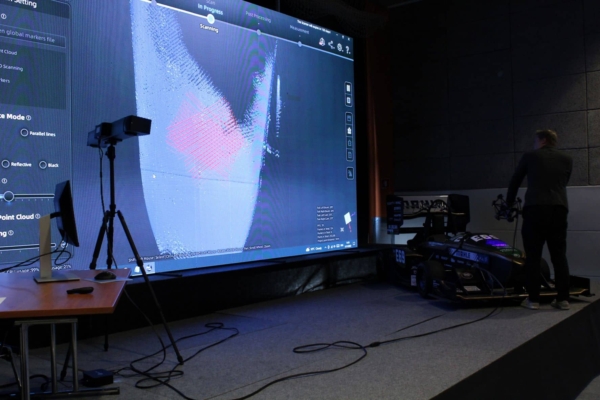

NIELS STENZEL - SHINING3D

This was followed by a lecture by our guest from Germany, Niels Stenzel, who presented Shining3D, their position on the market and their vision for the future. He mentioned many new developments, but first and foremost he presented their products and applications.

To top it all off, he gave a demonstration of 3D scanning on a very interesting object – a formula. The latter was brought to our guests just for us by the people behind this cutting-edge product – students from the Superior Engineering team. For the 3D scanning, he used an extremely sophisticated scanner, the FreeScan Trak, which captured a good part of the formula in less than a minute.

REVERSE ENGINEERING AND QUALITY CONTROL

After a short coffee break, our Peter started his work with a lecture on reverse engineering and quality control. He gave a presentation on what can be done later with the 3D scan data.

Reverse engineering is the process of recreating a model from the data. This produces a CAD model of the real piece, which can be used for reproduction or other purposes. On the other hand, quality control is a kind of verification of the finished piece, which may deviate from our ideal model drawn in the CAD software. In addition to the theoretical presentation, Peter gave a practical demonstration of quality control in Control X. With his ingenuity, he quickly determined the surfaces, parameters and tolerances, and the software then produced a measurement report itself, showing all the required information.

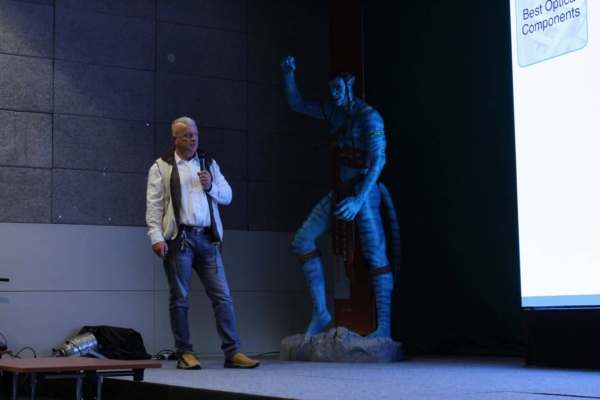

THE BIGGEST SURPRISE AT THE 3WAY OPEN HOUSE - THE AVATAR REVEAL

The most interesting point of the day for many was the following. The avatar has been revealed! That’s right, a 3D printed sculpture of an avatar that is almost as tall as the “real” Avatar. For purely practical reasons, we made a statue that was “only” 270 centimetres high, instead of three metres, as the latter would have been too big for our offices. All participants were of course able to have their photo taken with him and thus get a picture with the first “real” Avatar in Slovenia.

Some quick information:

- 72 kg of PLA material used

- Consists of 55 pieces

- 1460 hours of 3D printing

- The follow-up work took approx. 200 hours

We spent just over four months on the Avatar project, which was sometimes very demanding with the work that was going on. We will be making a special announcement about the latter, so all the secrets of the manufacturing process will remain a mystery for now, but we are certainly happy and excited about the final product after the unveiling. All the work is paid off with a piece of art like this, and you may soon see it somewhere other than in our premises, where for the time being it plays the role of “security guard” at the entrance. Among others, this is exactly what will be shown in December in the second part of “The Way of Water” at Cineplexx.

HAO YANG - INTAMSYS

After the unveiling of the avatar, lunch was served, and we took enough time for everyone to eat in peace. The lecture continued with our second guest, Hao Yang from Intamsys. He presented Intamsys and FFF 3D printing technology. Like us, he pointed out that Intamsys is focused on producing high-quality industrial 3D printers. Among other things, we had on display in the hall the two Intamsys 3D printers that we have in our premises – the Funmat Pro 410 and the Funmat HT.

E-PLUS-3D AND 3D METAL PRINTING

The last thematic lecture was on 3D printing of metal, given by our Robert. In this area, we are working with E-Plus-3D, a company that produces high-performance metal powder 3D printers for the market. In addition to selling these large machines, we are also trying something completely new, namely 3D printing metal on an FDM 3D printer. Thanks to the special LABS Gen 2 experimental extruder on the MakerBot Method X 3D printer, it is possible to print BASF material containing 80% metal powder and 20% polymer. After 3D printing, the piece must be sent for sintering to remove the plastic from the assembly. Of course, the latter shrinks a bit in the process, so we still have some testing to do around that. But we are thrilled that such a thing is possible nowadays!

PRIZE GAME

For the grand finale, we also had a raffle, which we ran live on an LCD screen. This time we really didn’t skimp on the prizes, as we gave away 10 reels of PLA filament, a Mayku FormBox, a FlashForge Adventurer 3 and a Shining3D Einstar. FormBox is a desktop vacuum forming machine, Adventurer 3 is our entry-level 3D printer and Einstar is our latest 3D scanner. Some of them left our event with not only more knowledge, but also practical prizes for creating in the 3D world.

At the end of the meeting, some of the participants soon left, while others and I took some time to have a pleasant chat. We consider this year’s “3WAY Open House” a great success. We know that it can always be better, and we believe that organising it will be easier every time, which is why we guarantee you an ever-higher standard of our events.

MEDIA AT THE "3WAY OPEN HOUSE"

We were also joined by our media partners, Computer News and IRT 3000, where you will also be able to read about our event. We take this opportunity to invite you to read all the latest developments in a wide range of technologies in these two media on a monthly basis.