FLASHFORGE GUIDER 3 IS DESIGNED FOR SMALL BATCH PRODUCTION

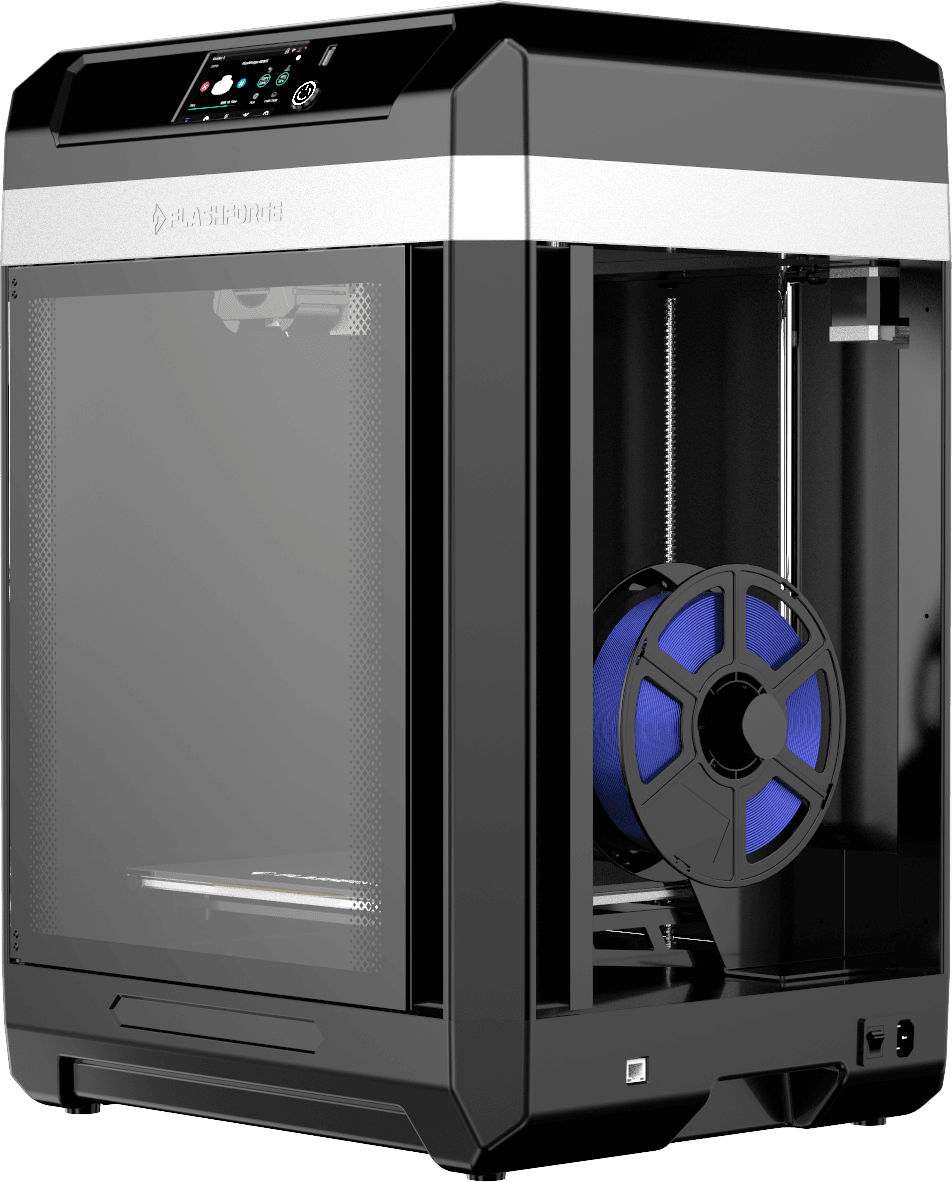

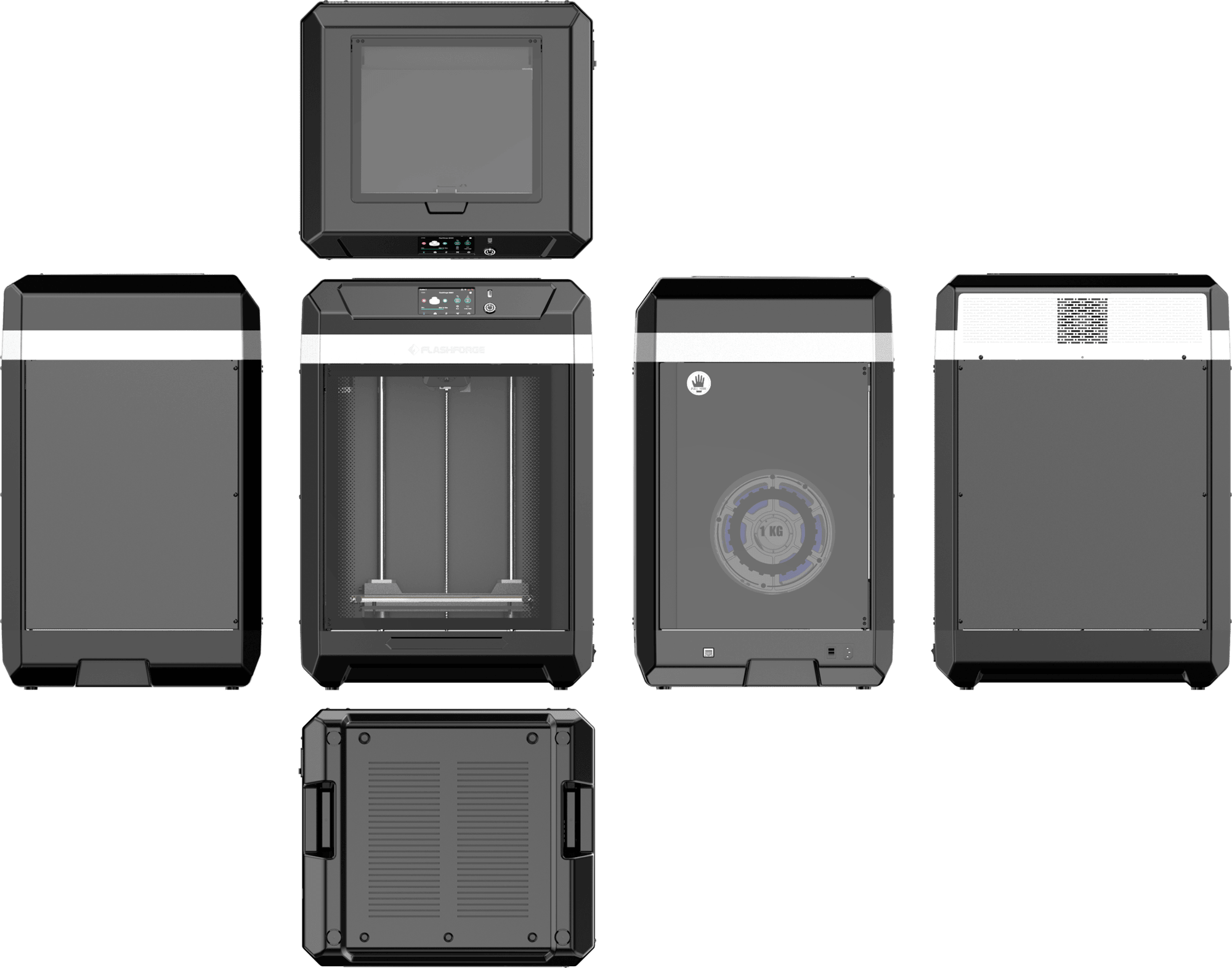

The FlashForge Guider 3 is a professional 3D printer for use in small batch production. With impressive 3D printing speeds of up to 250 mm/s, it is the ideal device for cost-effective small batch production for small and medium-sized enterprises. With its robust aluminium frame and lightweight yet durable ABS panels, the Guider 3 ensures stable 3D printing even after long hours of continuous operation.

The reduced weight and compact structure allow this 3D printer to be seamlessly integrated into any production environment. The powerful control system ensures stable and continuous 3D printing, making it suitable for a wide range of applications. It is lightweight and compact, and offers a simple and powerful control system. FlashForge Guider 3 thus provides an affordable solution for many applications.

AUTOMATIC START SYSTEM

Guider 3 can save the 3D printing status in case of an unexpected power failure and automatically resume 3D printing when power is restored.

INTEGRATED SYSTEM FOR REAL-TIME MANAGEMENT AND MONITORING OF 3D PRINTING

The FlashPrint 5 software, which comes with your 3D printer purchase, allows you to manage multiple devices in one place in an integrated way. So you can easily access all your 3D printers. With the integrated camera, the 3D printing process can be monitored in real time via FlashPrint 5 software. This way you can always keep track of your status.

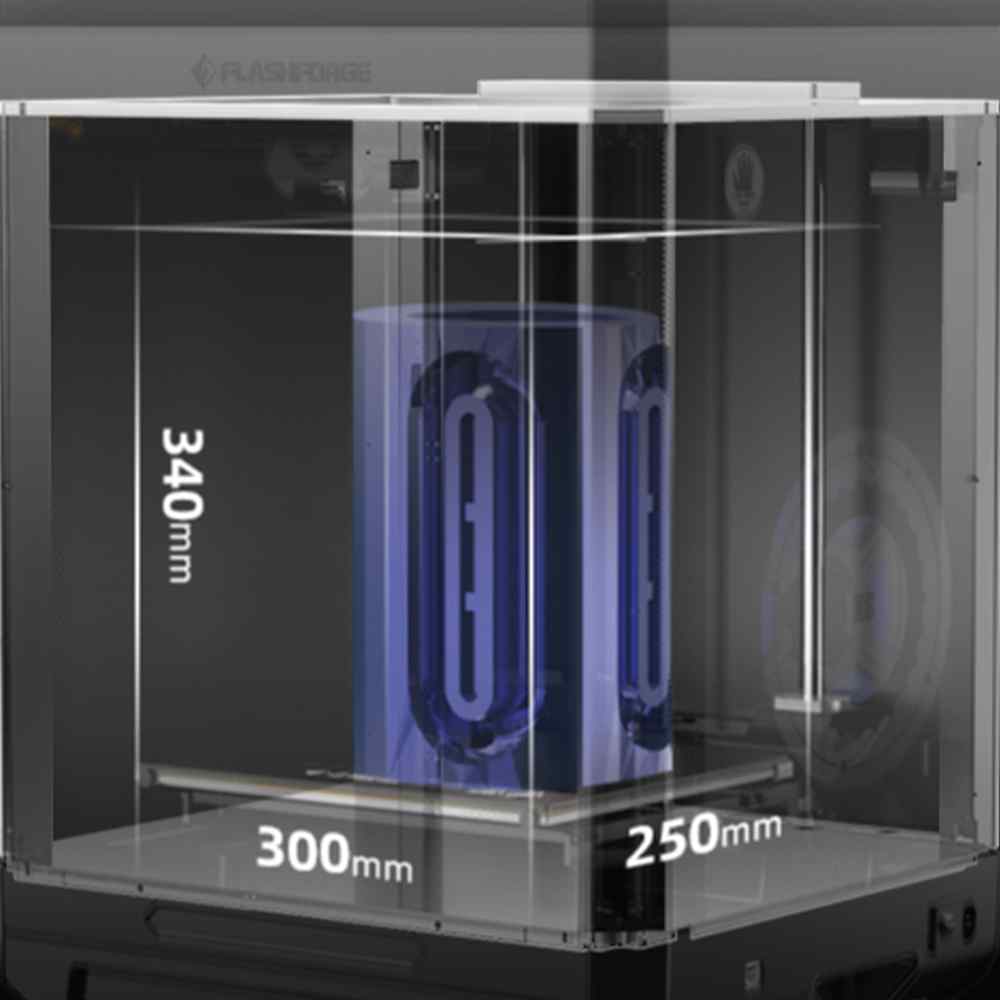

OPEN SYSTEM FOR DIFFERENT MATERIALS AND PRECISION 3D PRINTING

The high temperature extruder (up to 320°C) is compatible with a wide range of materials: PLA, ABS, PC, PA, HIPS, ASA, PETG, PA-CF, etc. It also supports other brands of materials. You can print models up to 300 x 250 x 340 mm, which is the maximum 3D printing volume of the Guider 3.

USE FLASHFORGE GUIDER 3

FlashForge Guider 3 can be used in many areas. It can be used as an aid at work. Designers and engineers can now quickly test different designs. It can be used in the learning process or for education, at home for DIYers who can use a 3D printer to fix something, and of course in companies for prototyping or small batch production.

GUIDER 3’S COMPACT DESIGN ALLOWS FLEXIBILITY

The new design has improved the use of interior space. While parts take up less space, this has increased the volume of 3D printing. The entire frame is made of aluminium and the casing is made of lightweight and durable ABS plastic and acrylic panels, ensuring stable 3D printing.

POWERFUL DUAL-PANEL SYSTEM

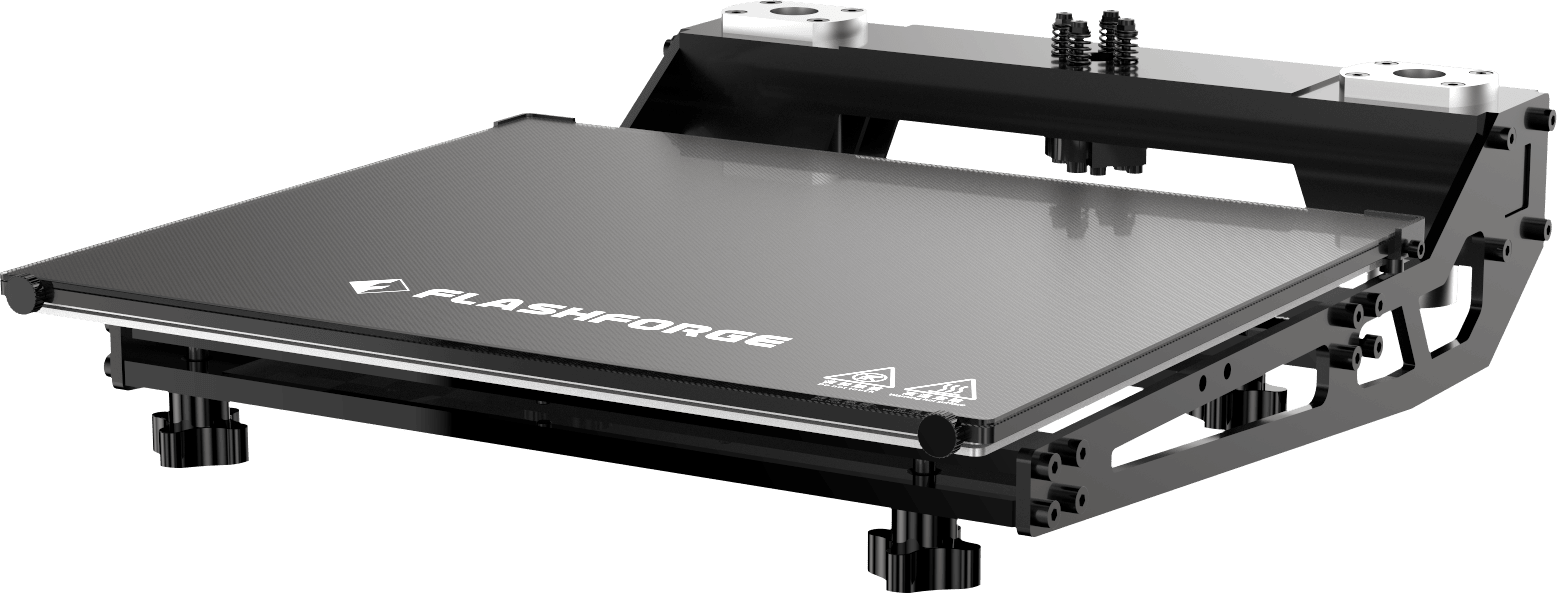

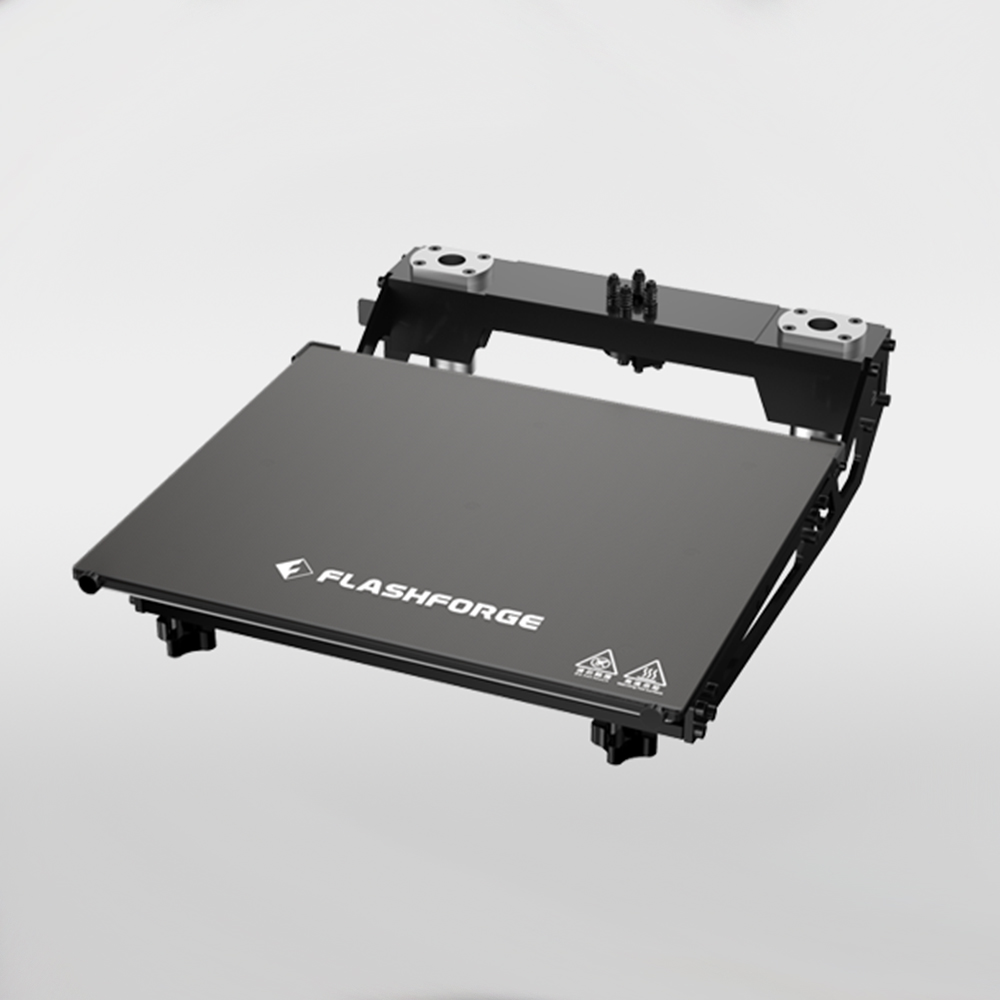

FlashForge Guider 3 offers two different working platform options: a glass mat and a flexible mat. Users can thus choose the working mat according to their needs. The glass working mat has a smooth and flat surface, making it easy to remove the models. This saves time. On the other hand, the flexible working mat is easy to bend, making it easier to remove large models, the working mat can be quickly replaced and the even heating over the entire surface ensures the best 3D printing results.

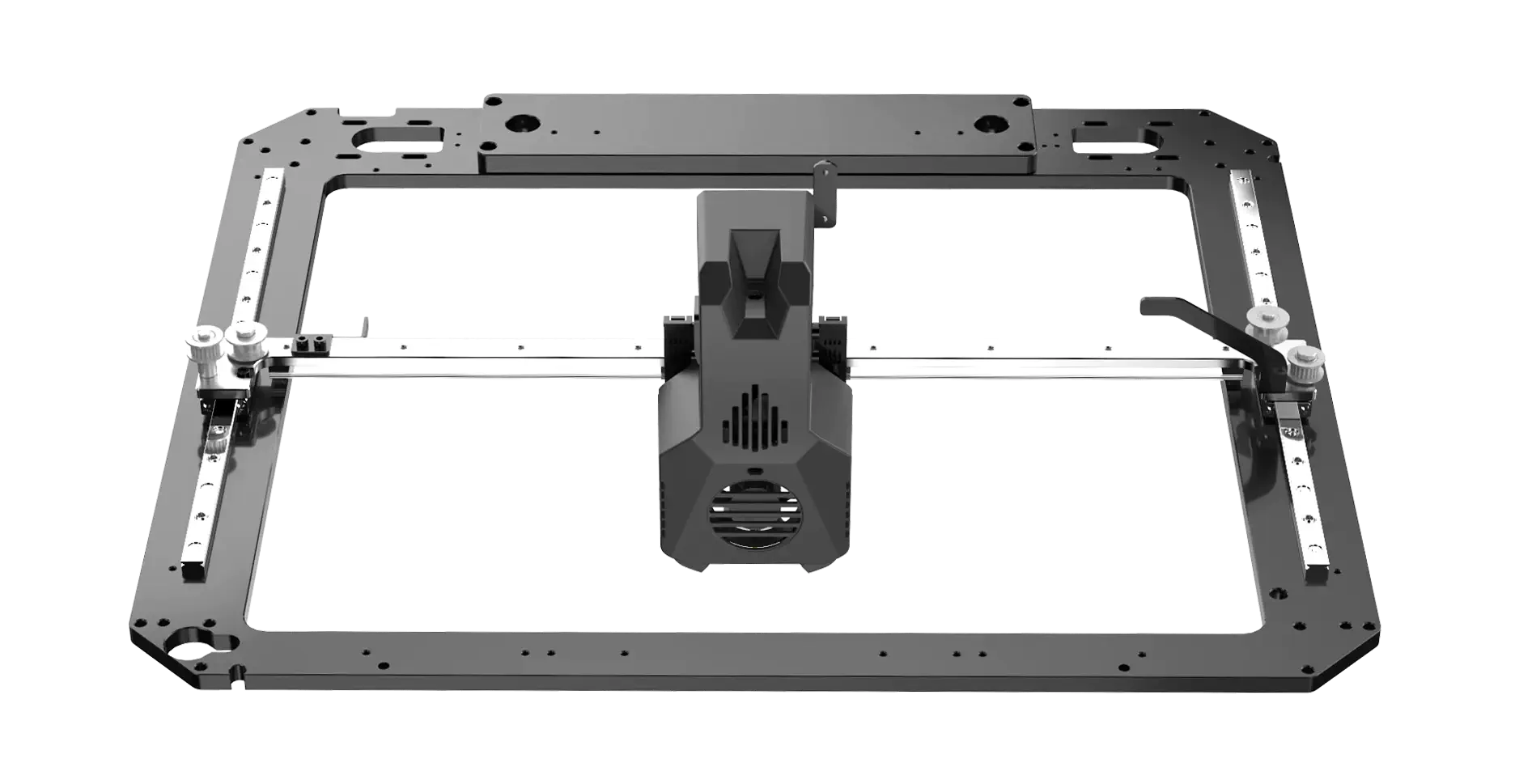

THE “CORE XY” STRUCTURE ENABLES EXTREMELY FAST 3D PRINTING

FlashForge Guider 3 contributes to an efficient workflow, enabling a rapid response to demand. Thanks to the “Core XY” structure of the guides, it offers smooth movement, supports high speed and quiet 3D printing, saving time, ensuring stable and efficient 3D printing.

UPGRADED CALIBRATION PROCESS

Calibration is an important first step before starting 3D printing. Guider 3 offers an optimised auto-calibration system to ensure quality 3D printing. Automatic calibration is handled by a precision built-in sensor that detects and stores initial plate alignment data and intelligently compensates for the plate height on the Z-axis during the printing process.

OPTIMISED EXTRUDER COMPOSITION

- Suitable for different filaments

- Double gearing increases pulling force by 150%

- Fewer problems with nozzle blockages

- Easy maintenance and quick nozzle replacement

ECONOMICAL, SAFE AND ENVIRONMENTALLY FRIENDLY 3D PRINTING

Sleep mode: if Guider 3 is not in use for a long time, it will automatically go into sleep mode. The screen and lights turn off, ensuring low power consumption during night-time projects.

Air filtration: the HEPA air filter can effectively filter dust, odours and particles generated during the 3D printing process, ensuring an environmentally friendly and safe working environment.

Auto Power Off: When 3D printing is complete, Guider 3 will automatically power off, allowing for more economical and safer operation.

Filament detection: the Guider 3 is equipped with a filament detection sensor. If the latter is worn out or the nozzle is clogged, it will automatically stop and remind you of the related problems, which can effectively prevent damage to the 3D printed part or the nozzle.

Reviews

There are no reviews in english yet.