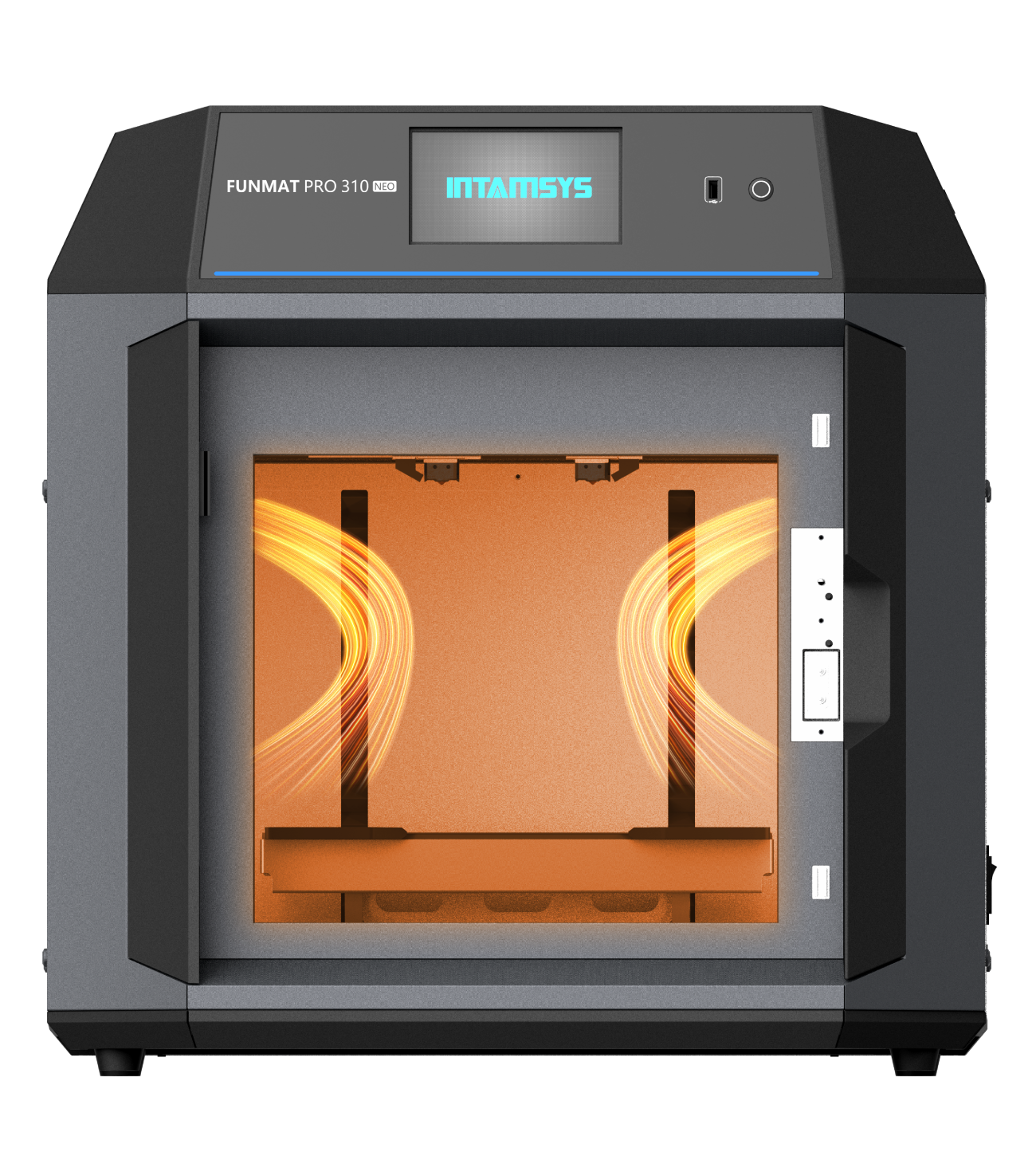

Intamsys FUNMAT Pro 310 NEO professional 3D printer

Intamsys FUNMAT Pro 310 NEO je industrijski FFF (Fused Filament Fabrication) 3D printer. Dizajniran je tako da ispunjava sve zahtjeve industrijske proizvodnje. Precizan je, moćan, dosljedan, učinkovit i pouzdan.

The Intamsys Funmat 310 NEO is in the category of ULTRA fast printers.

The 3D printer has an exceptionally high production capacity of 500 g/day, and with the mirroring or dual printing mode, it can achieve a performance of up to 1000 g/day. When printing, it can reach speeds of up to 500 mm/s, with an average printing speed of 250 mm/s. The acceleration during printing is 10000 mm/s².

The FUNMAT Pro 310 NEO is designed for high-speed printing. It features a control board for fast printing, advanced motion control algorithms, and a wide range of settings for printing different materials (material process packages). This ensures excellent surface finishing, resulting in smooth surfaces and exceptional dimensional accuracy even at high printing speeds.

The heated chamber of the Intamsys FUNMAT Pro 310 NEO printer

The thermostat chamber of the Funmat 310 NEO printer can be heated up to 100°C and maintains this temperature throughout the entire printing process (with a variation of only 5%). The chamber temperature allows for printing with true engineering plastics, which make the printed parts more stable and of higher quality.

Constant temperature in the chamber ensures:

- better adhesion between layers,

- reduces thermal deformation and shrinkage of the printed parts,

- significantly improves the mechanical properties of the printed part,

- improves the repeatability and consistency of the mechanical properties of the printed parts.

The FUNMAT Pro 310 NEO is compatible with various materials without the need to change the nozzle.

- High-performance thermoplastics: PPS, PPS-CF, PPS-GF.

- Engineering thermoplastics: PC, PC-FR, PC/PBT, PC/ABS, ABS-HS, PPA-CF, PPA-GF, PA12-CF, ABS+, ASA+, PA6/66, PA6-CF.

- Flexible materials: TPU95A.

- Biodegradable thermoplastics: PLA.

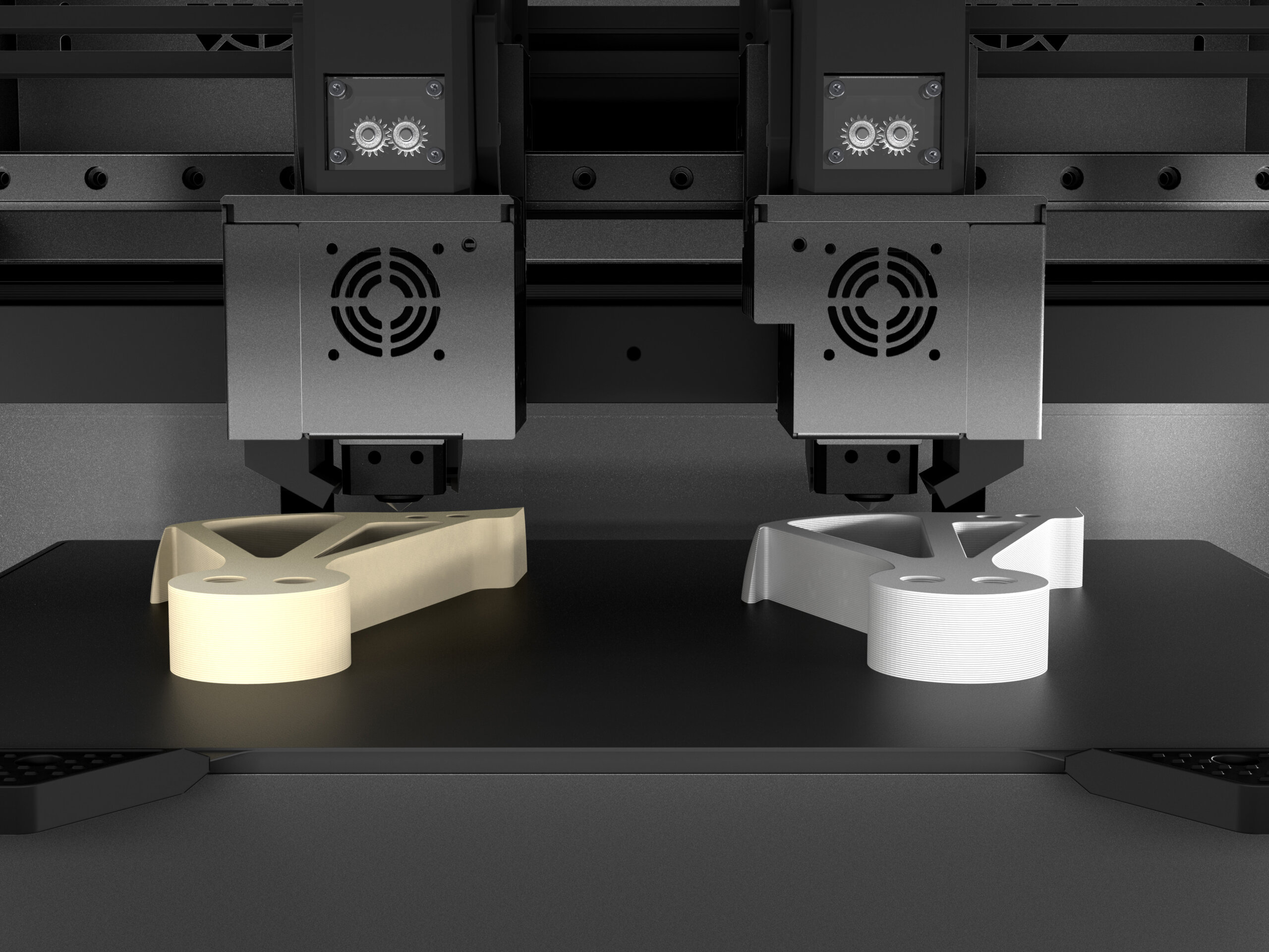

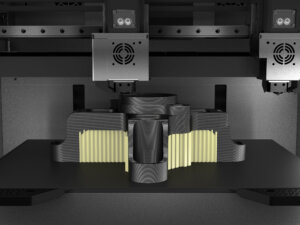

Independent Dual Extruders (IDEX) enable four printing modes

- Mirrored printing;

- Duplication;

- Dual printing/dual material printing;

- Printing support materials.

Printing with support materials enables top-notch quality when printing complex geometries. Intamsys provides fully water-soluble and easily removable support materials.

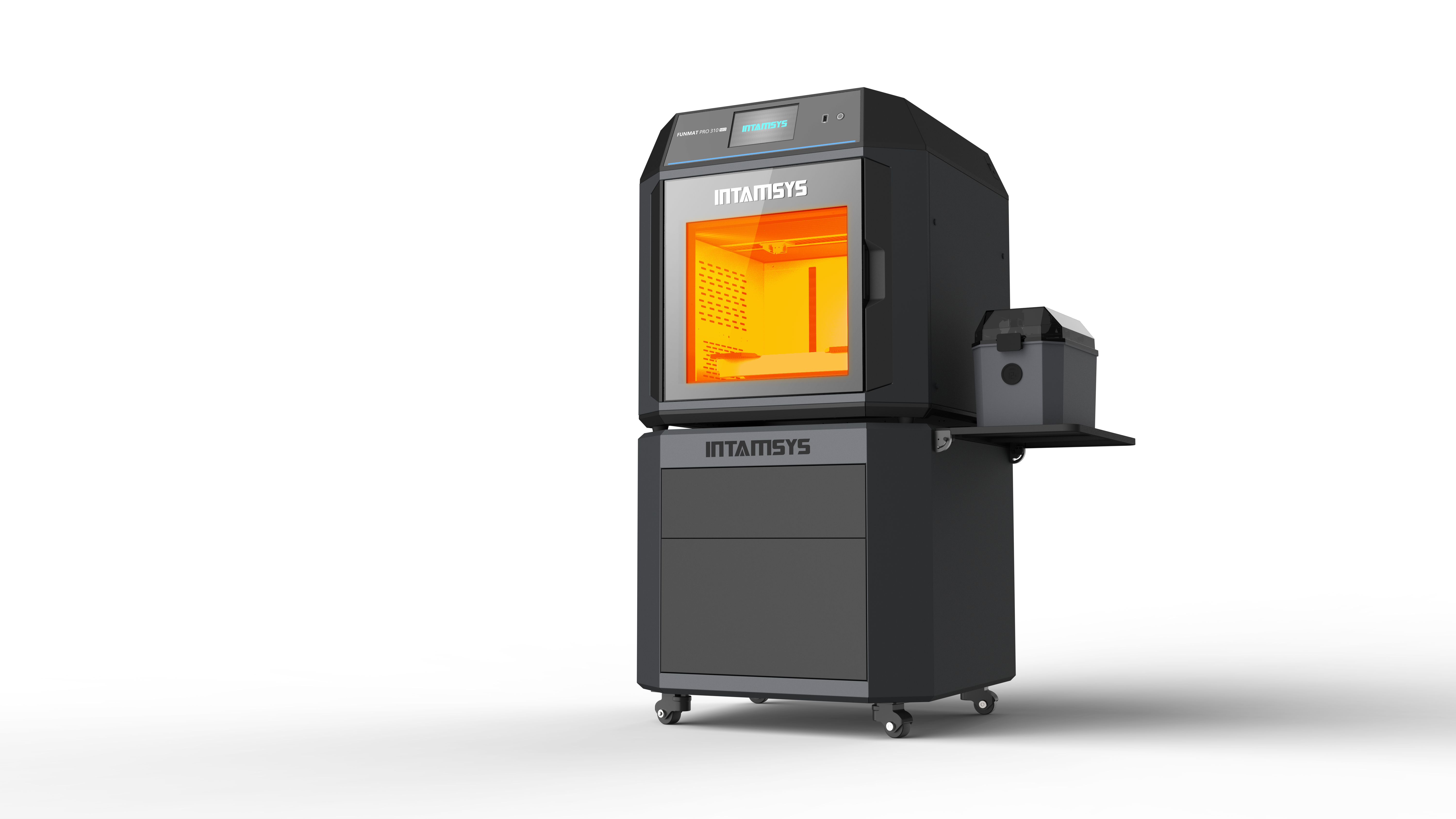

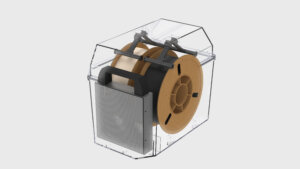

The INTAMBox provides optimal storage for filaments

- Closed design with dehumidification

- Built-in sensor for temperature and humidity monitoring

- Easy installation and maintenance

- Capacity: 2 x 1 kg

Working mat

The flexible build plate automatically calibrates and simultaneously allows for easy removal of printed models.

User-friendly interface

The Funmat Pro 310 NEO 3D printer features a user-friendly interface. It provides automatic task management and allows for standard API interfaces, ensuring seamless integration with MES.