When we first enter the realm of 3D printing, we often encounter challenges that can puzzle us. No worries, most of these challenges are completely manageable if we just know the right tips. Today, we’ll take a look at the five most common mistakes beginners make in 3D printing and how to avoid them, so we can enjoy flawless printing.

1. Improper leveling of the build plate

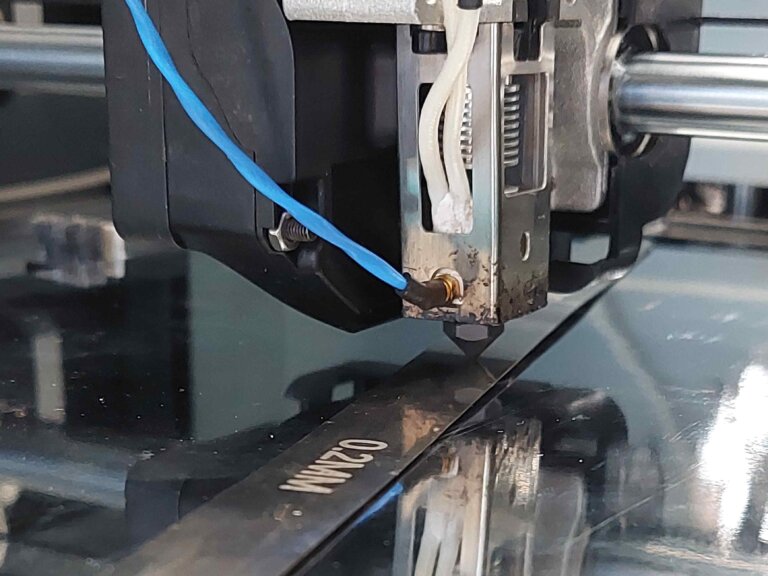

One of the most crucial steps in 3D printing is setting up the build plate. Improper leveling of the build plate can lead to poor adhesion of the first layer, uneven printing, or even nozzle collision with the build plate. To avoid this, it’s important to regularly and correctly perform the leveling procedure as outlined in the 3D printer’s instructions. Precision and consistency are key in this process.

2. Improper preparation of the build plate

In addition to leveling, proper preparation of the build plate is crucial to avoid instability and poor adhesion of the first layer, which can result in subpar and uneven 3D prints. The build plate should not be dusty or greasy. For better adhesion, adhesive or a special tape can be applied to the build plate. It’s also important to set the correct temperatures, as too high a temperature can cause deformation, while too low can result in poor layer adhesion.

3. Nozzle clogging

Another very common challenge in 3D printing is nozzle clogging. It often occurs due to improper temperature settings, inadequate filament storage (it begins to absorb moisture), or residue in the nozzle. To address this, ensure that the nozzle is clean and that the printer is properly calibrated. Utilize the “cold pull” method by heating the nozzle and then retracting the filament to remove any potential clogs. Regular maintenance and the use of high-quality 3D filament can help prevent potential clogs.

4. Using low-quality 3D filament

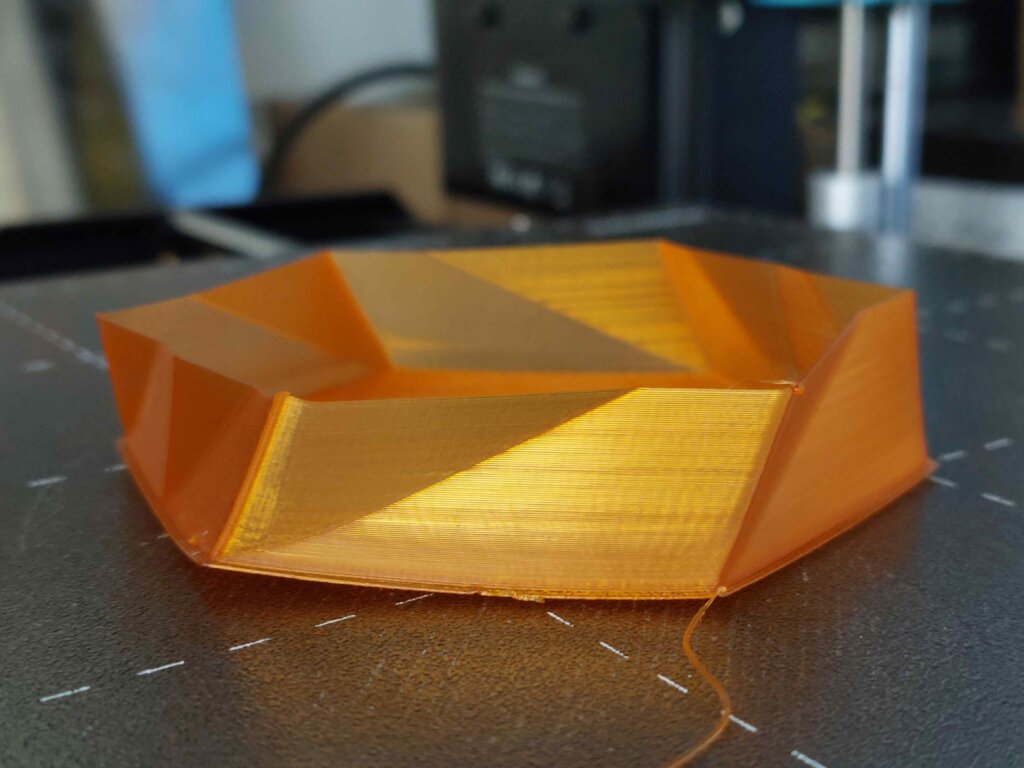

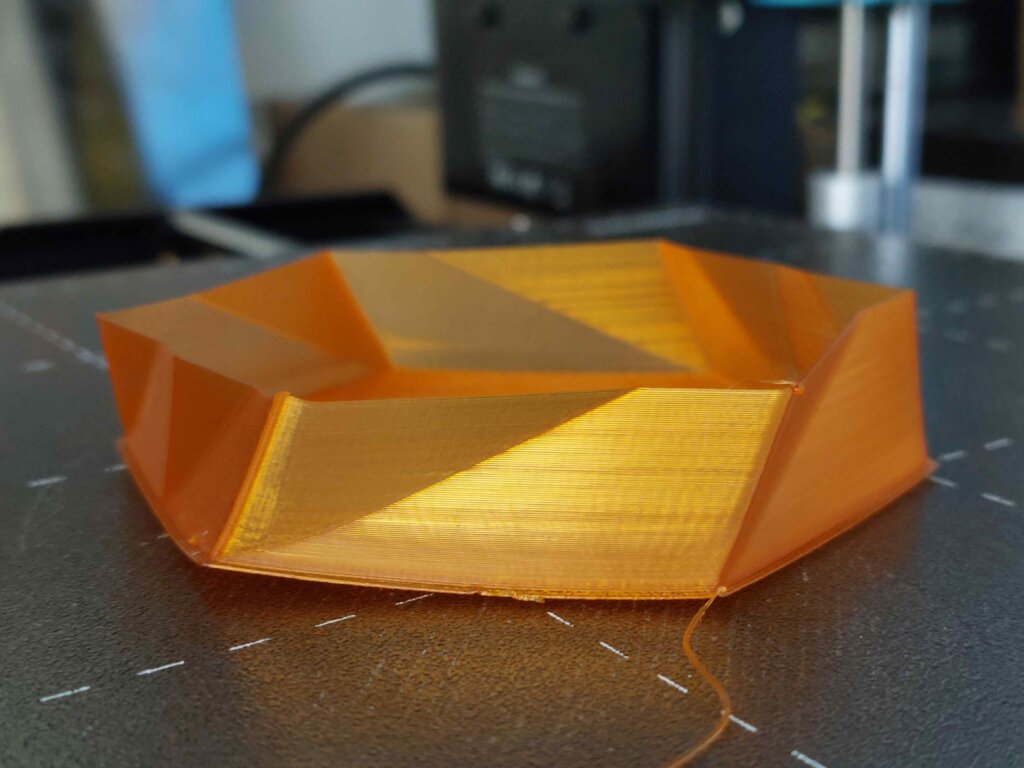

It’s important to know that the quality of the 3D filament is crucial. Using low-quality or moisture-absorbed filament can negatively impact:

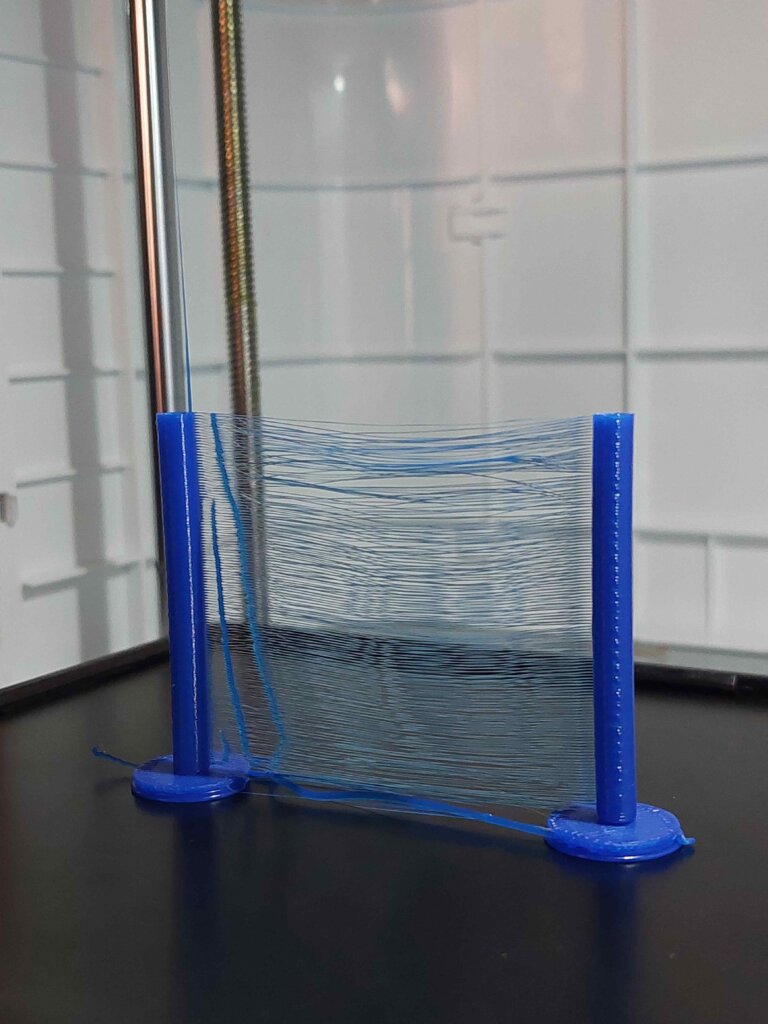

- Print quality: the model may be of poor quality due to uneven printing, poorly visible details, potential filament stringing, and the surface properties of the material may be inferior;

- Layer stability: due to higher moisture content, the layers may not adhere well during printing, reducing the strength and stability of the model;

- Extruder: moist filament can lead to poor nozzle flow or even clogging as moisture turns into steam during printing;

- Printer: moisture can cause corrosion of internal printer parts (e.g., heating blocks, nozzles), affecting the long-term durability of the printer;

- Odor in the printing room: low-quality or moist filament can emit an unpleasant odor during printing, which can be very troubling.

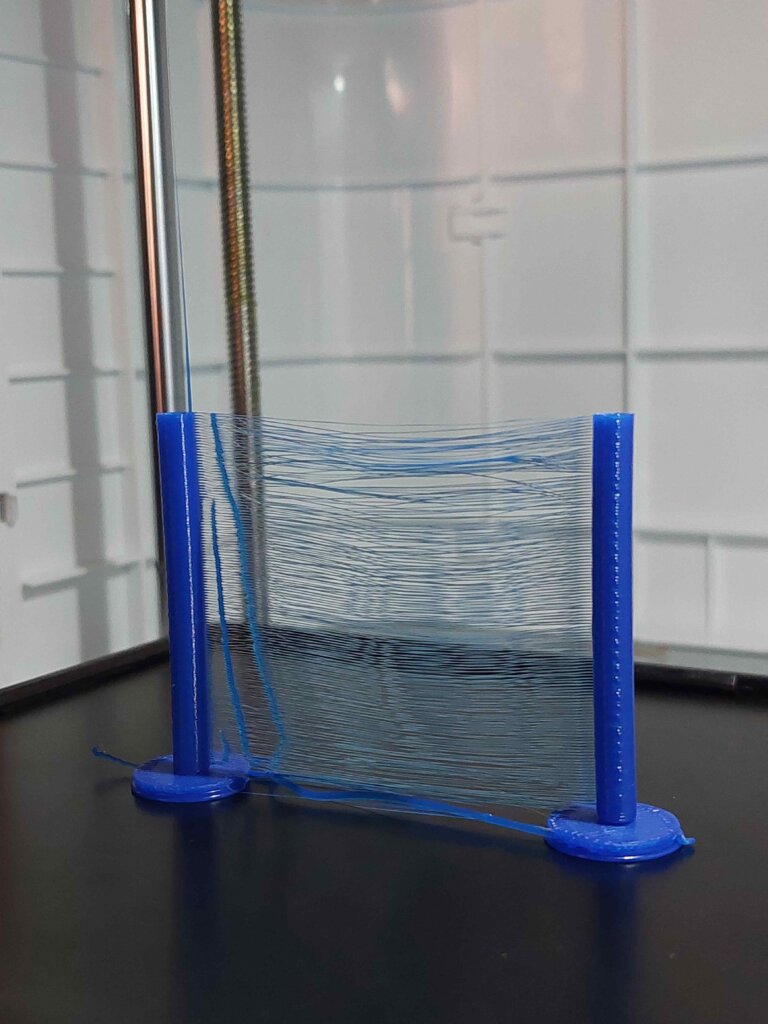

5. Inadequate print preparation

It’s also necessary to mention that inadequately planned 3D printing can lead to numerous issues, such as distorted, unstable models with errors or even holes and problems with supports. Incorrectly placed supports can lead to poorly printed models and wasted time for reprinting due to irregularities in the final model. Therefore, it is important that the models are optimized and properly prepared for printing. In principle, the program you use to prepare the 3D model will indicate if the model is optimized. However, it’s also good to pay attention yourself to ensure there are no holes or deviations in the model. Additionally, the orientation of the model on the build plate is also important. We position it in a way that minimizes the need for supports, as this will result in a more appealing and higher-quality print.

Final thoughts

3D printing offers exceptional opportunities for creation, but beginners often face challenges that can affect the quality and success of their projects. Understanding and avoiding the most common mistakes are crucial steps that lead to better preparedness for overcoming initial obstacles. With the help of these tips, even beginners will be able to enjoy a successful and creative 3D printing process.