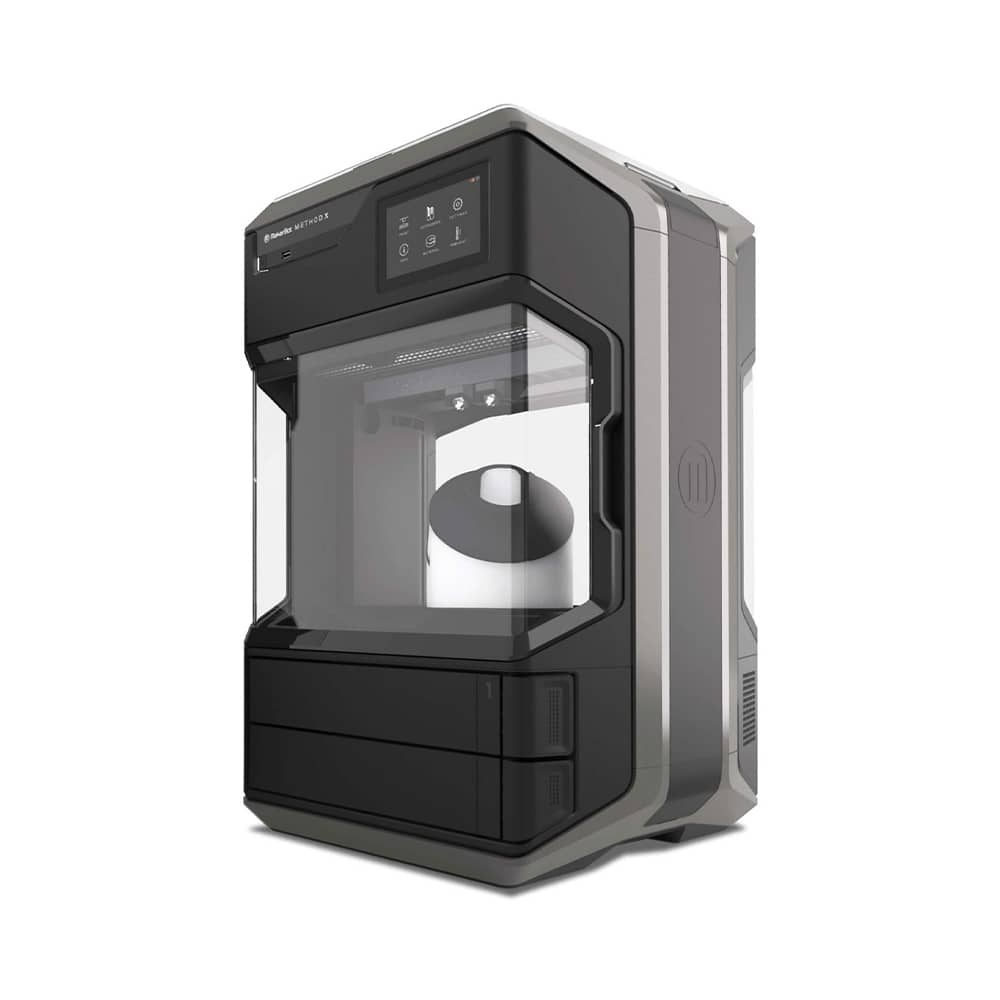

MAKERBOT METHOD X IS A PROFESSIONAL 3D PRINTER

MakerBot Method X is an advanced version of the MakerBot Method 3D printer, offering enhanced capabilities for professional 3D printing.

INDUSTRIAL CAPACITY

The MakerBot Method X is designed to deliver industrial-level performance in a desktop format. It has a robust metal frame and high-quality, precision components to ensure stability, accuracy and repeatability in 3D printing.

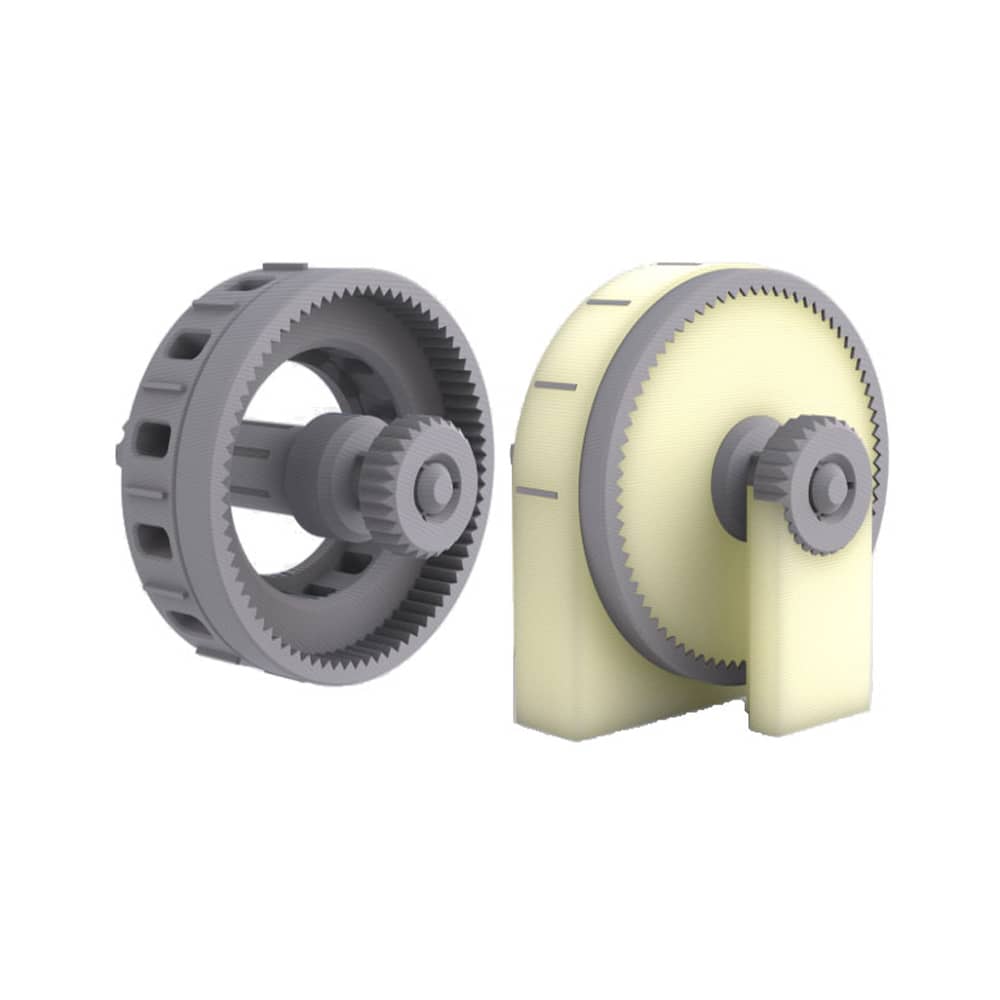

TWO “PERFORMANCE” EXTRUDERS

Similar to the Method, the MakerBot Method X is equipped with two extruders. This allows 3D printing with two different materials or colours at the same time, allowing for more diverse 3D printing.

3D PRINTING OF ADVANCED MATERIALS

Method X is specifically designed to process a wider range of materials, including high temperature and engineering materials. It supports specialised MakerBot materials such as ABS, ASA, nylon, carbon fibre, PETG and others, allowing users to create durable and functional prototypes and end-use parts.

COMPATIBILITY WITH MATERIALS

- When using the 1A extruder (included with purchase): PLA, TOUGH, PET-G, PETG-ESD, NYLON, ABS, ABS-R, ABS-EC, ABS-ESD, PC-ABS, PC-ABS-FR, PC-PBT.

- When using the 1C extruder: NYLON CARBON FIBER, NYLON 12 CARBON FIBER.

- When using the 2A extruder: PVA, RAPID RINSE, SR-30.

- When using the LABS extruder: SEBS 95-A, PETG CARBON FIBER, PAHT 9825, PET CF 9780, CF 9891, STAINLESS STEEL 316L, ABS CARBON FIBER, DURABIO, POLYLITE, POLYMAX PC, POLYMAX FR.

“MAKERBOT PRECISION CORE”

Method X uses the MakerBot Precision Core extrusion system, which uses a dual drive to ensure precise filament feeding and consistent extrusion. This technology enables 3D printing of a wide range of materials, including advanced engineering materials.

HEATED CHAMBER AND PRECISION COOLING

Method X has a closed and heated chamber that maintains a controlled temperature during the 3D printing process. This helps to reduce twisting, especially when working with technical materials. Method X also includes precision cooling fans to ensure optimal cooling and dimensional accuracy of 3D printed parts.

TOUCHSCREEN AND CONNECTIVITY

The MakerBot Method X offers a colour touchscreen for intuitive control and easy access to the 3D printer’s settings and functions. It also offers a variety of connectivity options including USB, Ethernet and Wi-Fi, allowing seamless file transfer and remote monitoring.

“MAKERBOT PRINT” SOFTWARE

Method is supported by MakerBot Print, a powerful software with advanced features for model preparation, prop creation and 3D printing monitoring. It provides a user-friendly interface and supports popular CAD file formats for efficient workflow integration.

IMPROVED WORKFLOW

Method X is designed to streamline workflow. It includes features such as automatic material loading, a built-in camera to monitor 3D printing remotely, and the ability to pause or resume 3D printing. These features increase productivity and user comfort.

SUPPORT

MakerBot offers comprehensive support, including online resources, tutorials and a dedicated user community. This support network provides users with easy access to information, troubleshooting and knowledge sharing.

Overall, the MakerBot Method X is a versatile and reliable 3D printer that combines industrial performance with user-friendly features. It offers professionals the possibility to produce high-quality designs with a wide range of materials, making it suitable for a variety of applications.