3D technology will upgrade your production processes

3D technology can be an extremely effective solution to many problems in the production process. Traditional methods are still the mainstay of production for most companies, but 3D technology is increasingly being introduced as a complement or replacement for a particular process. Many problems are easily solved with 3D technology.

WHAT OF 3D TECHNOLOGY CAN BE FOUND HERE IN 3WAY?

We are a one-stop shop for all 3D technology products, and recently there has been a growing demand for services, as 3D solutions are affordable and efficient. In addition to

CAD/CAM software

which have been around for a long time, 3D printers, which can be used to create almost anything, and 3D scanners have recently entered the scene. The latter allow data to be captured and used for reverse engineering or quality control. In many cases, 3D technology speeds up processes and gives more control. All this, of course, at a significantly lower cost than would otherwise be the case. 3D technology offers opportunities that are worth seizing.

Rated 5.00 out of 5 based on 1 customer ratingAdd to cart

Rated 5.00 out of 5 based on 1 customer ratingAdd to cart1.049,00 €Original price was: 1.049,00 €.754,00 €Current price is: 754,00 €. Rated 0 out of 5View More

Rated 0 out of 5View More3.499,00 €Original price was: 3.499,00 €.2.589,26 €Current price is: 2.589,26 €.

AUTOMATION, STANDARDISATION AND OPTIMISATION OF PROGRAMMING

Although the roots of CAD/CAM software date back to the middle of the last century, it has of course changed a lot since then. In the CAM area, we advocate

hyper

MILL

CAM software from Open Mind Technologies. We believe that with its many advanced modules, it offers the highest level of automation and standardisation of processes, allowing you to programme more efficiently. Simple processes will thus

hyper

MILL

will do the work for you, while you can focus on more complex tasks. The most advanced within

hyper

MILL

is certainly the “Virtual Machining Centre”, which is a perfect synthesis of the virtual and the real world.

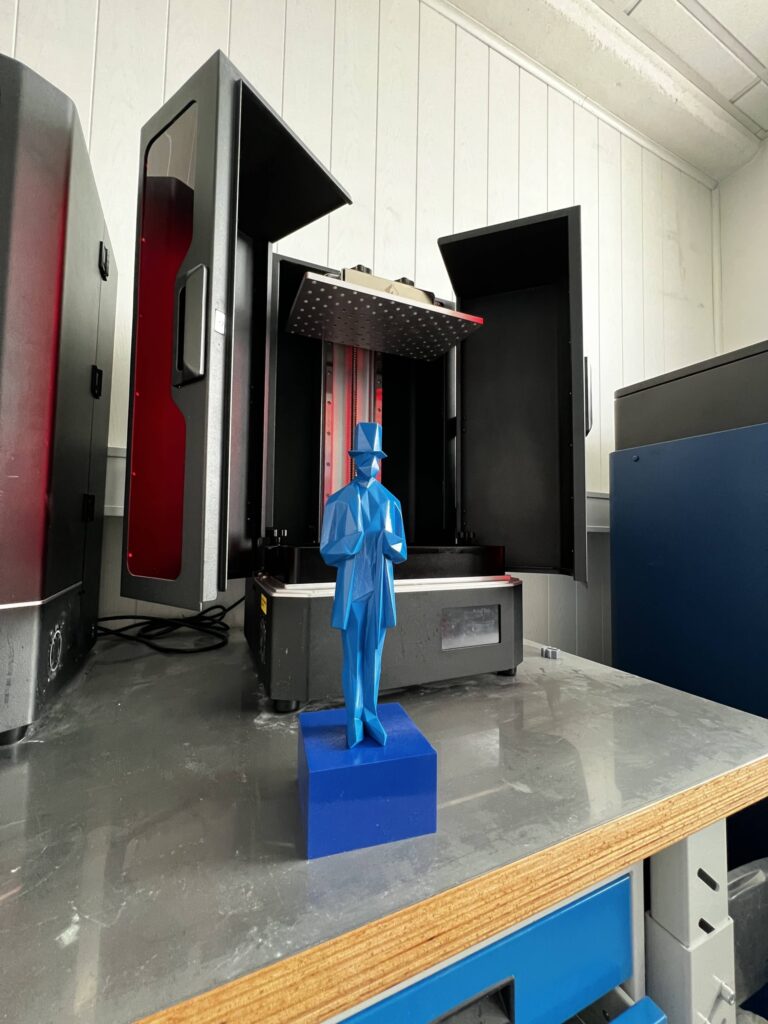

WITH 3D PRINTERS YOU CAN CREATE PRACTICALLY ANYTHING

It goes without saying that 3D printers are getting more accurate, bigger, faster and cover a wide range of materials, making them an increasingly important part of manufacturing. They are still most useful for prototyping, where you can get a finished product from a CAD model in just a few hours. This option is very time and cost efficient. 3D printing is also useful for small batch production. The advantage is, of course, that you can use a 3D printer to create practically anything. Complex shapes are really no problem at this point.

THE FASTEST GROWING 3D TECHNOLOGY - 3D SCANNING

Have you ever been in a situation where you wanted to get a CAD model of a certain piece, but because of time-consuming and imprecise measurements, you didn’t even go through with it? Or would you like to do a quality check after you have made a piece before you send it to the next stage? 3D scanning here opens up a whole new dimension. It gives you an easy route to a CAD model that you can use later for reproduction or quality control. 3D scanners are becoming more accurate, easier to use and will give you a complete 3D model.

LIVE 3D TECHNOLOGY?

Just like last year, this September is the perfect opportunity to learn about 3D technology in person, with the “3WAY Open House”. We will open our doors to all existing and potential customers. We will give you a detailed overview of all the services we offer, plus, of course, the products for which we are agents. There will also be a big surprise and plenty of prizes, as well as morning coffee and lunch during the break.

Watch the video from last year: