Quality control of castings with FreeScan UE 11

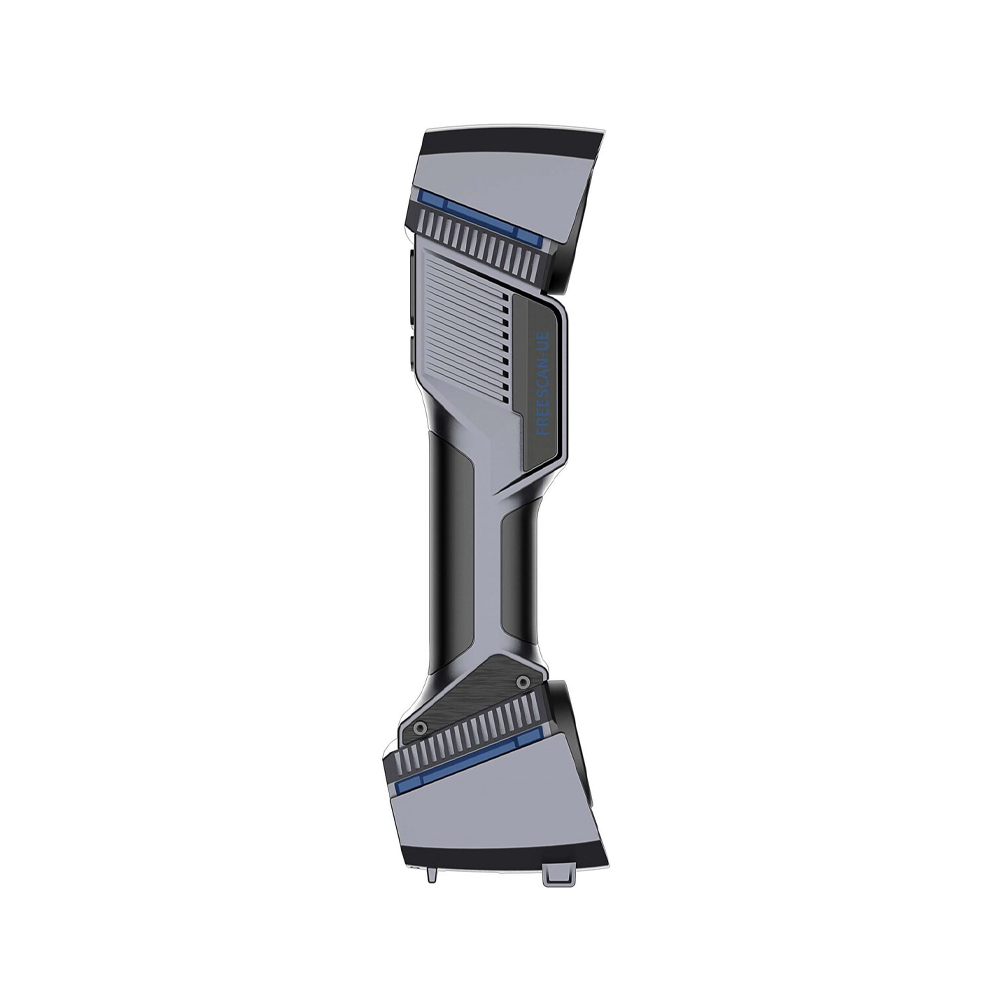

Quality control is important for accurate and reliable inspection of parts, which is crucial for product quality in the industrial and manufacturing sector. 3D scanning technology has proven to be an excellent tool in the digitization process, which facilitates the workflow, and makes it significantly shorter at the same time. With the increasing affordability and availability of metrology 3D scanners, the gap between 3D scanning and other measurement technologies is closing. In this case, Shining3D FreeScan UE 11 was used to inspect the castings.

3D SCANNING OF CASTINGS USING FREESCAN UE 11

High-quality metrology 3D scanners like the Shining3D FreeScan UE 11 are becoming more and more affordable, but it still takes some time to learn how to operate them. The first thing that a measurer should focus on is learning how to capture data with a 3D scanner and how to process the data in the program. In this case of inspecting castings, it was demonstrated how accurately industrial parts could be inspected using a 3D scanner.

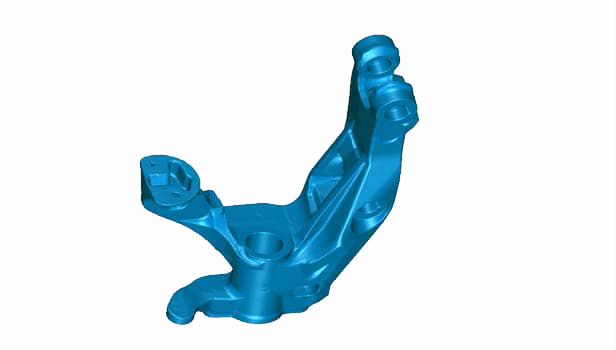

HIGH QUALITY CASTINGS FOR DIFFERENT APPLICATIONS

In this particular case, the castings have some very complex characteristics. They are irregularly shaped and have multiple curved surfaces, which presents a challenge for manual measurement. The complexity of the measurement is mainly represented by the large volume of work and the precise measurement of the inside of the casting.

Taking all factors into account, using the high-precision 3D scanner FreeScan UE 11 for casting quality control was the ideal solution.

3D SCANNING & QUALITY CONTROL OF CASTINGS

In the first step of the process, 3D scanning was used to obtain the external shape of the castings. The castings were difficult to move, so this is where the FreeScan UE 11 3D scanner excelled, as it was easy to hold and move around. It weighs only 670 g. In this way, they easily obtained all the necessary information about the castings.

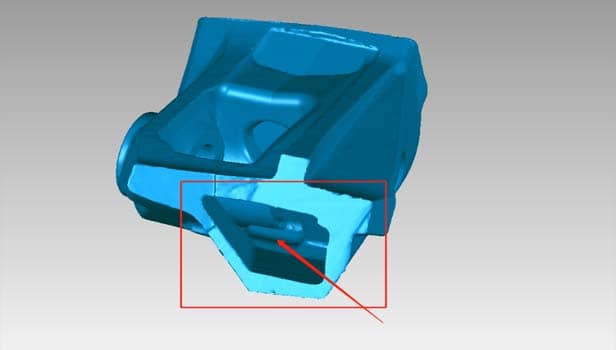

3D SCANNING OF THE INTERIOR OF CASTINGS

To inspect the inside of the casting, they must be cut open to obtain information about the internal shape. Thanks to the software’s seamless clustering capabilities, complete error-free data can be obtained.

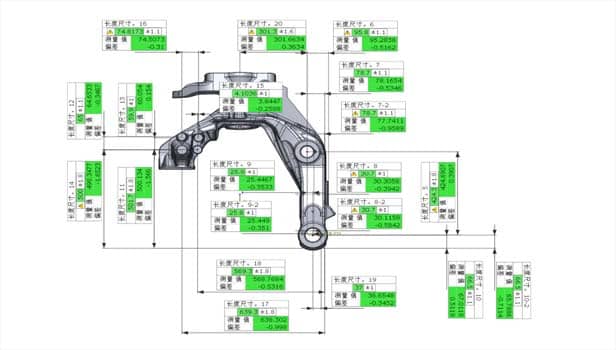

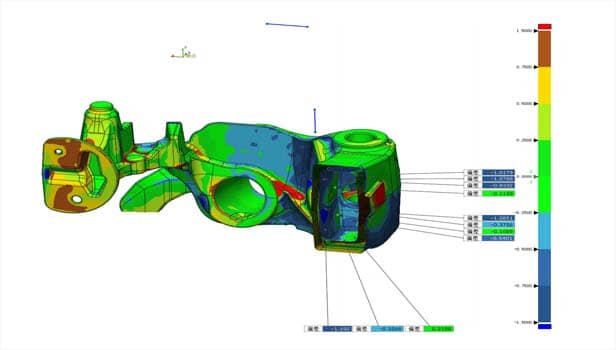

QUALITY CONTROL WITH GEOMAGIC CONTROL X

The obtained data were imported into Geomagic Control X, which is used for quality control. The use of quality control software in direct connection with FreeScan UE 11 enables direct output of the required data. In this case, it was data about the external appearance and internal shapes and dimensions. A total of 46 points were measured and detailed results were obtained.

Non-contact, highly accurate, and efficient measuring tools are the key to detailed and accurate quality control results. The FreeScan UE 11 3D scanner can be flexibly operated in a wide range of settings, which enables 3D scanning of large-format objects and quick access to complete and high-quality data. All this provides strong support for detailed quality control reports.

OTHER 3D SCANNERS IN OUR SHOP

- Stock Out

Shining3D FreeScan Trak ProW

- Stock Out

Shining3D FreeScan Trak Nova

- Stock Out

Shining3D EinScan Libre - Wireless 3D Scanner

- Sale!

Shining3D Einstar - odprta embalaža

1.049,00 €Original price was: 1.049,00 €.671,00 €Current price is: 671,00 €.