Reverse engineering & 3D scanning – new tools for an old job

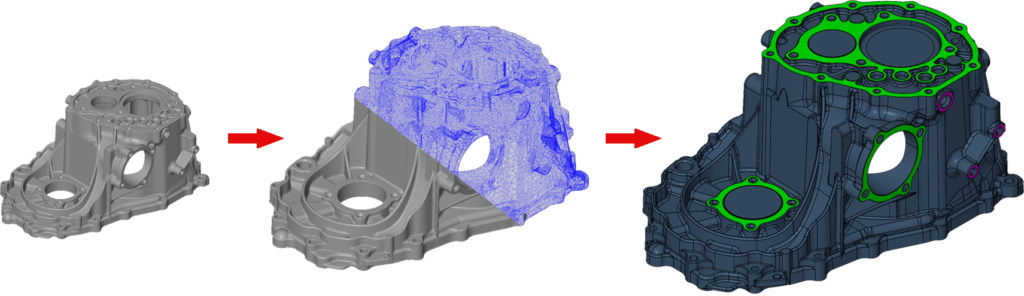

Reverse engineering is nowadays increasingly associated with the process of converting the geometry of a physical object into a digital 3D model or CAD model. The name itself suggests that it is the reverse of a typical manufacturing workflow. The process clearly requires certain information about the real piece. The fastest way to get the latter is with another modern branch of 3D technology – 3D scanning.

REVERSE ENGINEERING SOMETIMES

Not long ago, reverse engineering involved extremely time-consuming work before implementation. Measurements on the piece were usually taken with beak gauges and hexagons. All of this has severely limited the scope of reverse engineering applications, as it has been very cost-ineffective and, above all, time-consuming. As it stood, it was a rather useless method, despite its necessity.

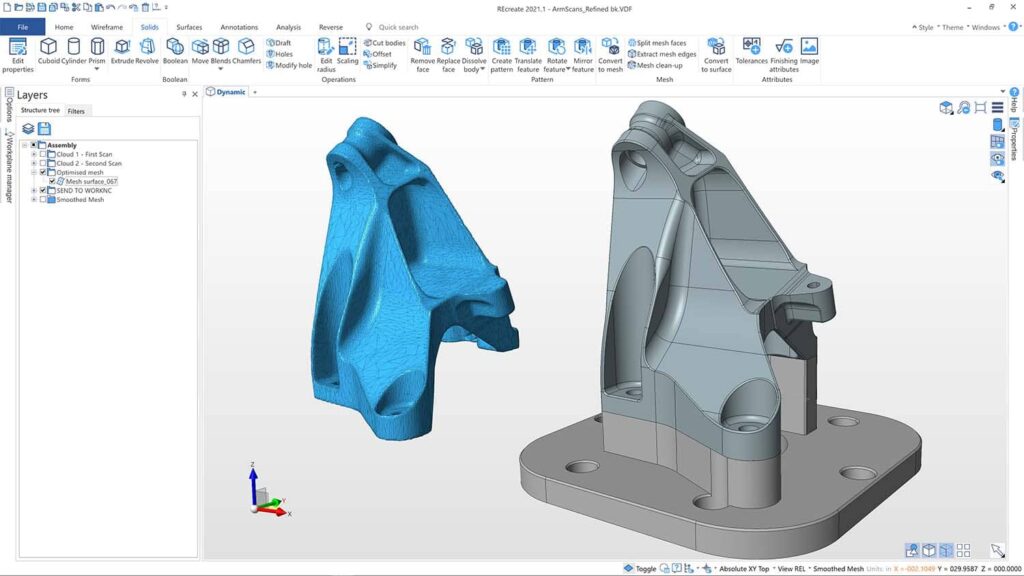

... AND TODAY

The measurement phase of a physical object has undergone a remarkable evolution, with the advent of 3D scanning technology, which can efficiently capture the geometry of even the most complex parts in an extremely fast way and, above all, with much greater precision. Today, it is possible to scan an object several metres long and wide in less than half an hour using 3D laser scanning. The Shining3D FreeScan UE Pro can perform such a task with an accuracy of up to 0.02 mm.

3D scanning has enabled a wider use of reverse engineering beyond simple comparative analysis and reproduction of pieces. It is now a precise method that can also be used to improve the shape of pieces.

-

Rated 5.00 out of 5 based on 1 customer ratingAdd to cart

Rated 5.00 out of 5 based on 1 customer ratingAdd to cart1.049,00 €Original price was: 1.049,00 €.754,00 €Current price is: 754,00 €.

MAIN APPLICATIONS OF 3D SCANNING AND REVERSE ENGINEERING

Reverse engineering with 3D scanning offers many possibilities for product creation, development and production. In general, the different uses of reverse engineering can be divided into three main applications: reproducing pieces, creating variations of existing pieces, or developing completely new pieces based on an existing environment or object.

1. RECREATING EXISTING PIECES

One of the most popular applications is the re-creation of damaged or worn parts that are not available from the original supplier or do not have the relevant documentation. This is a common problem when working with old machines or vintage vehicles, and is always difficult to do with hand tools.

2. IMPROVING EXISTING PIECES

The second goal of reverse engineering is to use digitised parts to make improved versions of parts, not just reproductions of them. In this case, it is a method that can significantly reduce the time and cost of making parts from scratch, as well as ensuring the perfect fit of components belonging to larger assemblies.

3. CREATING NEW PIECES BASED ON EXISTING ONES

The advent of 3D scanning has enabled another reverse engineering application that uses digitised parts as a reference to create entirely new parts. This procedure is usually used when a tight fit is required on a complex existing part.

MAIN APPLICATIONS OF 3D SCANNING AND REVERSE ENGINEERING

As you may have read, reverse engineering is an extremely efficient method for many applications. However, the quality of the data capture is crucial to achieving good results in the downstream process, so the choice of 3D scanner and its capabilities and features also plays an important role in the success of the overall process.