Quality control of large objects with FreeScan UE

Quality control of products and services is becoming an increasingly important link in process optimisation. The aim is to maximise efficiency, which is achieved through precision workmanship or service. Quality control plays an important role in optimisation, as it is about checking the work done accurately and providing feedback. We will show you a nice example of how to implement quality control in a work process.

OFFICINE FOGIARINI HAS DIGITISED ITS PROCESSES

Officine Forgiarini was founded in 1962 and is based in Italy. With a 60-year tradition, it covers industrial automation, abrasive machines and custom machining of large objects. Over the years, by focusing on the needs of their customers and delivering effective, value-added solutions, they have gained the trust of many users around the world.

Over the years, Officine Forgiarini has encountered a number of problems. The team members have found solutions that make Officina Forgiarini’s business long-lasting. They decided to digitise their production, incorporating quality control for optimisation. The problem with business development is most often the lack of appropriate methods for reviewing the work process.

Many of the parts produced by Officine Forgiarini are large and obtained by turning or milling. After machining, they lacked quality control in the most feasible form. They were therefore used to check the parts produced and ensure that they met the requirements, in particular what the ring diameters were, etc. This has a direct impact on the progress of the next step in the process. If the parts are not qualified, the installation will not be successful. The latter then have to be reprocessed, which increases the work time and prevents delivery within the agreed deadline.

QUALITY CONTROL WITH 3D SCANNING AS A SOLUTION FOR PROCESS VERIFICATION...

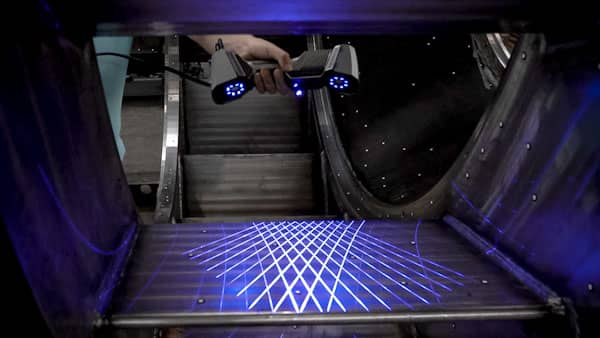

Shining3D has a simple but highly accurate digital solution – quality control with the FreeScan UE 11 3D scanner. The latter is a convenient and highly accurate device that can provide fast 3D scanning of large objects.

To solve this problem, Officine Forgiarini decided to work with Shining3D, which incorporated the FreeScan UE 3D scanner mentioned above into their process.

HOW IS QUALITY CONTROL CARRIED OUT?

Example on part of a Kaplan turbine:

- The appropriate number of markers shall be affixed to the entire turbine section

- 3D scanning with FreeScan UE 11

In the process of 3D scanning large objects, cumulative errors can occur during the process of assembling each scan frame. To obtain accurate information on the position of the markers, a single coordinate system is therefore used to eliminate the latter and to ensure precise control of the scanning of large objects.

The data is imported into the Shining3D software, from which the full 3D data is extracted.

The 3D scan data is imported into the quality control software, including arc diameter measurement and inspection of the assembly interface.

THE BENEFITS OF QUALITY CONTROL?

Quick 3D inspection of large parts. 3D scanning of large objects and inspection for piece conformity can be done in one day.

Solving the problem of recycling. If a piece fails inspection, it can be directly adjusted without having to be returned during assembly.

THE FUTURE IS BRIGHT

Thanks to the collaboration with Shining3D and the high precision of the FreeScan 3D laser handheld scanner , Officine Forgiarini has successfully supplied many machines and other products. Quality control has helped to achieve consistency in the parts machined. They will continue to strive for excellence and follow the latest strategies to optimise the production of professional machines or pieces.

ALL OUR 3D SCANNERS:

- Ni na zalogi

Shining3D Transcan C

- Akcija

Shining3D OptimScan-5M Plus (Rabljen, kot nov!)

32.940,00 €Original price was: 32.940,00 €.18.300,00 €Current price is: 18.300,00 €. - Ni na zalogi

Shining3D OptimScan-5M Plus

- Ni na zalogi

Shining3D FreeScan UE Pro 2 - wireless 3D scanner

- Ni na zalogi

Shining3D FreeScan UE Pro

- Akcija

Shining3D FreeScan Trio 3D Scanner (Copy)

40.258,78 €Original price was: 40.258,78 €.36.234,00 €Current price is: 36.234,00 €. - Ni na zalogi

Shining3D FreeScan Trio 3D Scanner

- Ni na zalogi

Shining3D FreeScan Trak ProW

- Ni na zalogi

Shining3D FreeScan Trak Nova

- Akcija

Shining3D FreeScan Combo 3D skener (Rabljen, kot nov!)

16.299,00 €Original price was: 16.299,00 €.14.640,00 €Current price is: 14.640,00 €. - Ni na zalogi

Shining3D FreeScan Combo

- Akcija

Shining3D Einstar Vega – wireless handheld 3D scanner

2.439,99 €Original price was: 2.439,99 €.2.118,99 €Current price is: 2.118,99 €. - Akcija

Shining3D Einstar 3D skener (Rabljen, kot nov!)

1.049,00 €Original price was: 1.049,00 €.610,00 €Current price is: 610,00 €. - Akcija

Shining3D Einstar - odprta embalaža

1.049,00 €Original price was: 1.049,00 €.671,00 €Current price is: 671,00 €. - Akcija

Shining3D Einstar

1.049,00 €Original price was: 1.049,00 €.754,00 €Current price is: 754,00 €. - Ni na zalogi

Shining3D EinScan SP V2

2.799,00 € - Akcija

Shining3D EinScan SE 3D skener (Rabljen, kot nov!)

1.598,99 €Original price was: 1.598,99 €.793,00 €Current price is: 793,00 €. - Ni na zalogi

Shining3D EinScan SE

1.599,00 €Original price was: 1.599,00 €.1.199,25 €Current price is: 1.199,25 €. - Ni na zalogi

Shining3D EinScan Pro HD

- Ni na zalogi

Shining3D EinScan Pro 2X V2